1.9 Ton Electric Excavator

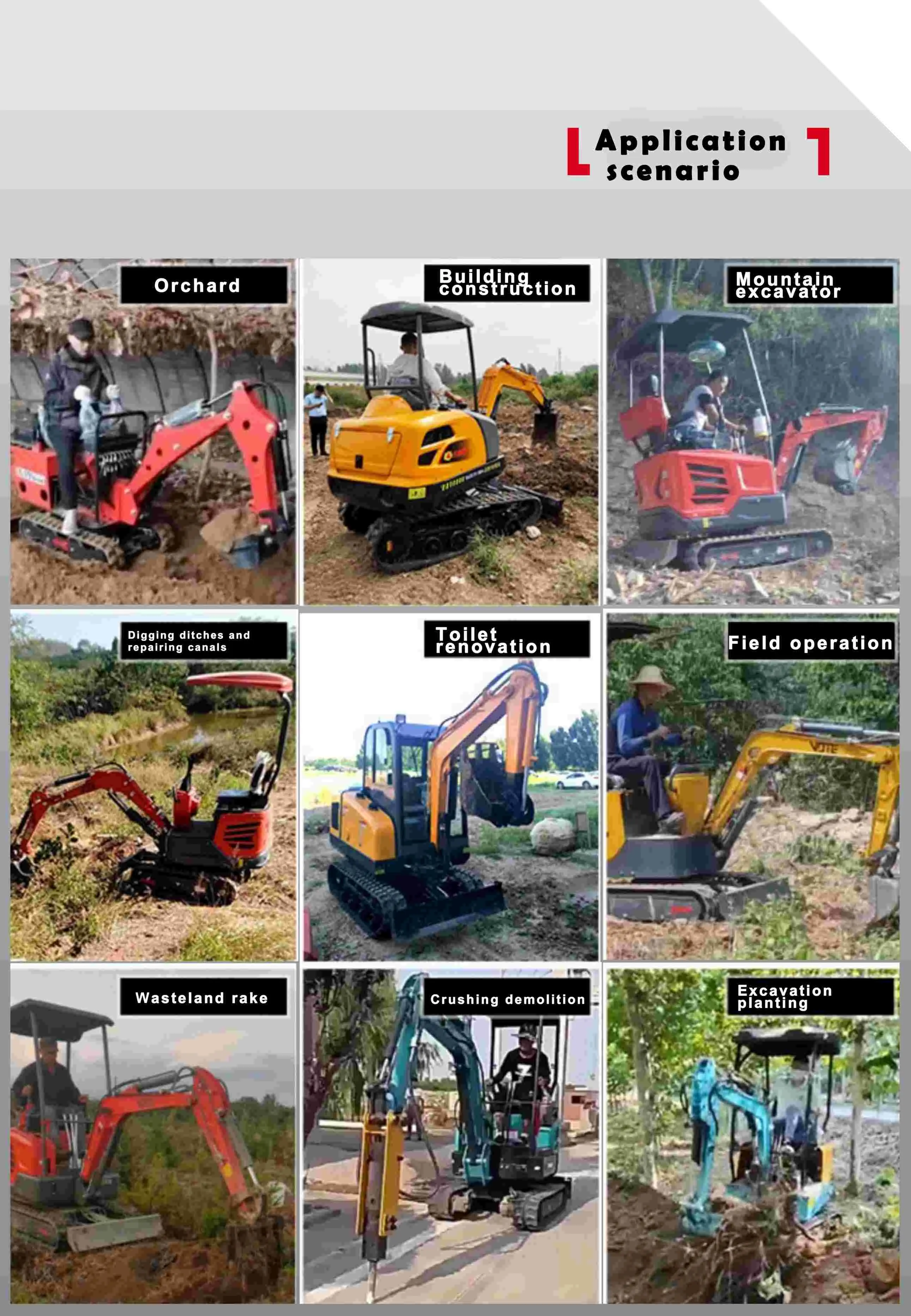

The SE19 is a flexible and efficient 1.9-ton electric excavator. Its compact body and small turning radius allow it to easily operate in narrow spaces, demonstrating exceptional adaptability in confined environments such as indoor renovations and agricultural greenhouses. The electric system combines zero emissions with low noise, enabling precise and rapid positioning while significantly improving work efficiency in enclosed spaces.

A Detailed explanation of the Comprehensive Performance of the 1.9-ton Electric Mini Excavator

Outstanding environmental performance

1.Zero-emission operation

This equipment adopts a pure electric drive system, completely eliminating the emission of harmful gases such as carbon dioxide (CO₂), nitrogen oxides (NOx), and particulate matter (PM) during operation. This feature makes it an ideal choice for construction in environmentally sensitive areas, including densely populated urban centers, indoor Spaces with limited ventilation conditions, nature reserves, and other working conditions with extremely high air quality requirements, effectively supporting green and pollution-free construction.

2.Low-noise operation

The operating noise of the electric micro-excavator is significantly lower than that of the fuel-powered equipment of the same level. The motor runs smoothly without combustion, detonation or mechanical strong noise, greatly reducing the noise interference to the surrounding environment. The equipment can thus operate continuously in areas with strict noise control, such as at night, around residential areas, hospitals and schools, expanding the effective construction period and reducing the problem of disturbing the residents.

Significant economic advantages

1.Low energy cost

The unit price of electric energy is lower than that of diesel, and its price trend is more stable without the risk of sharp fluctuations. Long-term use can save users a significant amount of energy costs, especially suitable for engineering teams that require the collaboration of multiple devices and high-frequency operations, effectively reducing the overall operating costs.

2.The maintenance cost is extremely low

The structure of the electric power system has been significantly simplified, eliminating complex and high-frequency maintenance components such as pistons, crankshafts, and fuel injection systems of fuel engines. The "three-electricity system" (battery, motor, and electronic control) adopts a highly integrated and maintenance-free design, requiring almost no daily maintenance. This significantly reduces the downtime caused by mechanical wear and the maintenance costs for replacing engine oil, filters, etc. The life cycle maintenance cost is approximately 30% to 50% lower than that of fuel-powered equipment.

Efficient and all-round working performance

1.Compact structure, flexible and mobile

The whole machine weighs 1.9 tons and adopts a compact structure and short tail design, featuring an extremely small working and turning radius. It can easily move through extremely narrow Spaces such as urban alleys, old residential areas, greenhouses, orchards and interior decoration sites, and flexibly complete multiple tasks such as excavation, transportation and leveling.

2.Precise control and efficient operation

Equipped with an advanced electronic control hydraulic system and intelligent control technology, it can achieve millimeter-level fine motion control. The operator can precisely adjust the excavation depth, Angle and force, significantly enhancing the construction quality and efficiency. It is particularly suitable for high-precision operation scenarios such as pipeline laying, landscape shaping and indoor grooving.

3.Strong power and reliable performance

Although it is an electric model, the motor can instantly output high torque. The maximum digging force of its boom and bucket is on par with or even better than that of fuel-powered excavators of the same tonnage. Even in complex working conditions such as hard clay and crushed stone mixtures, it can still stably and efficiently complete excavation, crushing and loading operations, meeting the power demands of the vast majority of small and medium-sized projects.

Comprehensive and thoughtful safety design

1.Multiple protections for electrical safety

The equipment is equipped with multiple electrical protection mechanisms such as overcurrent, overvoltage, leakage and short circuit, which can monitor the system status in real time. Once an abnormality occurs, it will automatically cut off the power for protection immediately, fundamentally preventing potential safety accidents caused by the electrical system and ensuring the safety of personnel and equipment.

2.It operates stably and has strong anti-overturning ability

Through a low center of gravity design and a reasonable counterweight layout, the entire machine can maintain excellent stability under various working postures. Even on uneven ground or slope conditions, the equipment can still operate safely and stably, greatly reducing the risk of overturning and ensuring continuous safe operation.

Model | Parameter | Model | Parameter |

weight(KG) | 1920 | Maximum excavation dig deep C | 2500 |

Transport length | 2350 | Maximum vertical digging depth D | 1785 |

Wooden case lengthA | 3000 | Maximum excavation radius E | 3350 |

Overall widthB | 1100 | Minimum radius of turn F | 1587 |

Total heightC | 2240 | Standard engine brand | KubotaD722 |

Turntable widthD | 990 | Emission standard | Country 4 / US 4 / Euro 5 |

Total chassis widthE | 1100 | Engine power (KW | 10.2KW/2500RPM |

Track width F | 180 | Telescopic side swing | sway |

Wheel track G | 1082 | Standard with bucket(MM) | 400 |

gauge H | 895 | Bucket capacity(M) | 0 |

Platform clearance I | 400 | cab | optional |

Minimum ground clearance J | 160 | air conditioner | optional |

Maximum excavation height A | 2800 | ||

Maximum unloading height B | 1980 |

This 1.9-ton electric mini excavator deeply integrates environmental protection concepts with high-end engineering performance. With a pure electric power system at its core, it achieves zero emissions and low-noise operation during the construction process. It not only eliminates exhaust pollution but also significantly reduces the interference of noise to the surrounding environment, truly reshaping the new standard of green construction. It stands out particularly in terms of economy. The low energy consumption and stable cost of electric drive, combined with the significant reduction in maintenance requirements brought about by the simplification of the power system, have significantly lowered the full life cycle operating costs for users.

The equipment combines outstanding flexibility with precise operation capabilities. Its compact body and tailless design enable it to easily navigate through complex and narrow Spaces such as urban renovation alleys, modern greenhouses, interior decoration sites, and ecological reserves. Meanwhile, its advanced electronic control and hydraulic system support millimeter-level fine control, making it perfectly competent for high-precision tasks such as pipeline laying, landscape shaping, and precise excavation. Meanwhile, this model has established a comprehensive safety guarantee system, integrating multiple electrical protection mechanisms and a low center of gravity anti-overturning structure to ensure stable and safe operation in various working conditions such as slopes and rough ground.

Overall, this excavator is not only suitable for traditional earthwork operations, but also demonstrates high adaptability in modern urban renewal, precise management of agriculture and forestry, construction in confined Spaces, and areas with high environmental protection requirements. It has become a benchmark solution for promoting industrial upgrading and achieving sustainable development.

FAQ:

1.What products does the company mainly produce?

We focus on the research and development, design and production of a full range of excavators, bulldozers and other construction machinery, and are a leading enterprise in the field of large-scale energy-saving mining machinery and micro electric machinery in China. Our mining equipment and micro electric products have reached the international advanced level in technology and can provide customized solutions based on the specific needs of customers.

2. What are the payment methods?

The payment terms we usually accept are as follows: 30% of the total order amount should be prepaid as a deposit after the contract is signed, and the remaining 70% of the payment should be settled before the goods are dispatched.

3. How long is the delivery cycle?

The standard delivery time is 30 to 45 days after receiving the deposit. Inventory products can be dispatched immediately, while custom orders may require additional delivery time, depending on the specifications.

4. Which transportation methods are supported?

We offer flexible and diverse logistics solutions, covering various routes such as road, sea and air transportation. Most of the equipment can be transported by container or bulk cargo to ensure safe and efficient delivery.