Why does the excavator have high fuel consumption? How can fuel consumption be reduced?

The fuel consumption of an excavator is an important part of the daily cost expenditure, which directly affects the user's profit. Many people may wonder why their excavator consumes more fuel than others. In fact, there are several factors that secretly "consume" your fuel:

Long-term idling

Idling refers to the state of the engine running empty, that is, the engine is "chugging" when the excavator is not in operation. During the daily operation of the excavator, the equipment at many construction sites idles for as long as 40% to 50% of the time. During idling, the fuel burned by the engine does not create any value, which is equivalent to "burning money".

Take a piece of equipment that works 2000 hours a year as an example. If the idling time reaches 40%, and calculated based on the fuel consumption of about 3.7 liters per hour of idling, this piece of equipment will generate approximately 20,000 yuan more in fuel costs in a year, which is a considerable expense.

To reduce fuel consumption: You need to immediately reduce the idling time.

Reduce the idling time before shutting down. New engines do not require idling, while some previous engines need to idle for 2 minutes.

(1) When loading or unloading, if the truck waits for more than 5 minutes, turn off the engine.

(2) Before starting work every day, preheat the equipment for 3 to 5 minutes, and the preheating time should not be too long.

(3) If the engine is equipped with an idling shutdown system (the system will automatically turn off the engine after the idle time set by the operator), turn on this function.

(4) When the operator takes a break, has a meal, etc. and the equipment is not in operation, turn off the engine.

(5) Effectively manage construction vehicles and reduce idling through measures such as improving the driving route.

2.Poor construction site management

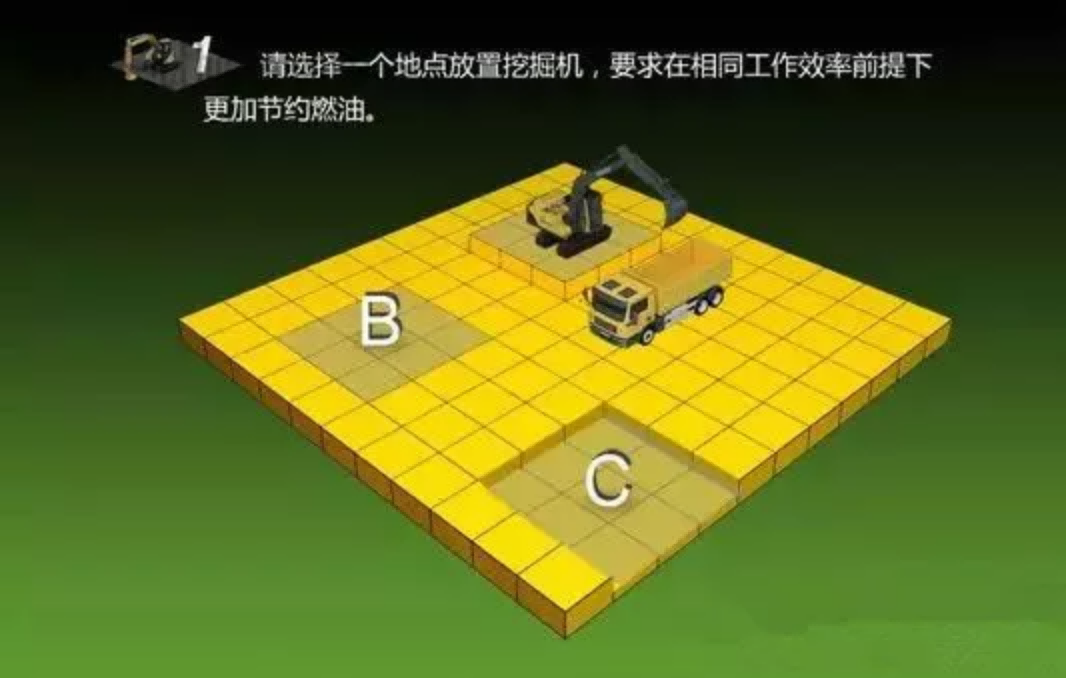

In different construction sites, factors such as the operation and layout of the equipment will affect the overall fuel consumption and production efficiency of the excavator. Grasp two "degrees" to quickly find the secrets of fuel savings and high efficiency.

3.Loading height

When the excavator works on a high platform, the height of the high platform is preferably equal to the length of the stick. At this time, the fuel efficiency is the highest. For the same work, the least amount of fuel is consumed. If the height of the high platform is not enough, it will not only increase the slewing time and fuel consumption, but also make it difficult to fill the bucket.

4.Slewing angle

During the loading operation of the excavator, the slewing angle of the excavator must not exceed 60 degrees, and a range of 30 to 45 degrees is more appropriate. The smaller the angle, the faster the slewing, the higher the output, and the less the fuel consumption.

5.Insufficient tire pressure

Research shows that the correct use of radial tires can save up to 10% of fuel consumption. Among them, tire pressure has the most significant impact on fuel efficiency. When the tire pressure is insufficient, the running resistance of the excavator increases, the fuel consumption increases, and the output will also decrease due to the unstable movement of the equipment.

6.Operator's operation level

Surveys show that a highly skilled operator can effectively reduce fuel consumption by up to 10-12%. Moreover, 30% of contractors believe that a high-level operator is the key to the success of the business! A good operator should have sophisticated construction experience, excellent driving skills, and rich construction knowledge to improve production efficiency and reduce fuel consumption.

Today, let's have some popular science and provide you with some fuel-saving tips for excavator operation.

Before sharing, imagine yourself as an excavator. Saving fuel for the excavator is equivalent to making the work easier for yourself, so you can better understand the principles.

01

When the excavator is loading, if possible, try to be at a higher position. If there is no condition, create the condition to stand at a high position and make the truck park at approximately the same height as the working surface. The reason is simple. Is the effort the same when you lift a stone to your knee and to your head? How much "effort" can be saved specifically? Compared with direct low-position excavation, it can shorten the cycle time by about 12%, reduce fuel consumption by about 8%, and increase the operation efficiency by about 40%, which are not small figures.

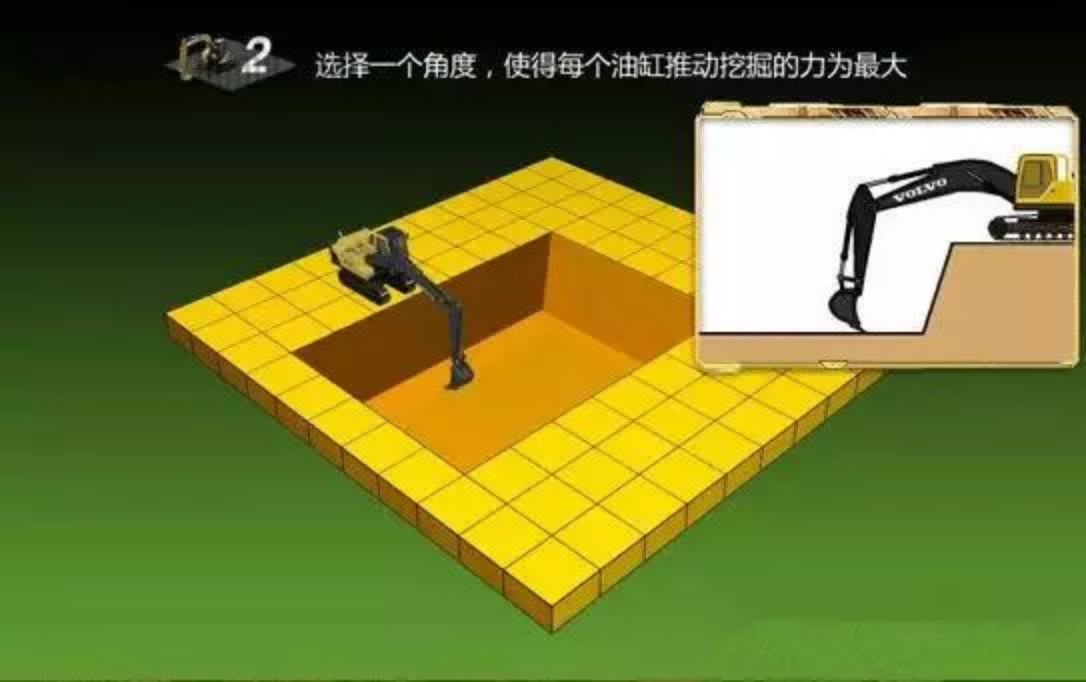

02

When the bucket cylinder forms a 90° angle with the connecting rod, and the head rod cylinder forms a 90° angle with the head rod, the force exerted by each cylinder to push the excavator is the greatest.

03

When excavating on natural ground, keep the bucket or ripper floor angle at about 30 degrees and retract the stick. When the stick is close to being vertical, the stick force is at its maximum, enabling it to bear a greater load. These two points are like lifting something with your arms bent, which saves effort

04

When starting to excavate, do not extend the stick to its maximum working range. It is best to start at around 80% of the range. (When the stick is at its maximum working range, the digging force of the stick is the smallest, making the excavation difficult.) Newcomers should pay special attention to this point

05

The digging range of the stick: The angle of the stick ranges from 45° on the far side to 30° on the inner side. There will be slight differences depending on the digging depth, but generally, operate the boom and bucket within this range, and do not operate until the end of the cylinder's stroke.

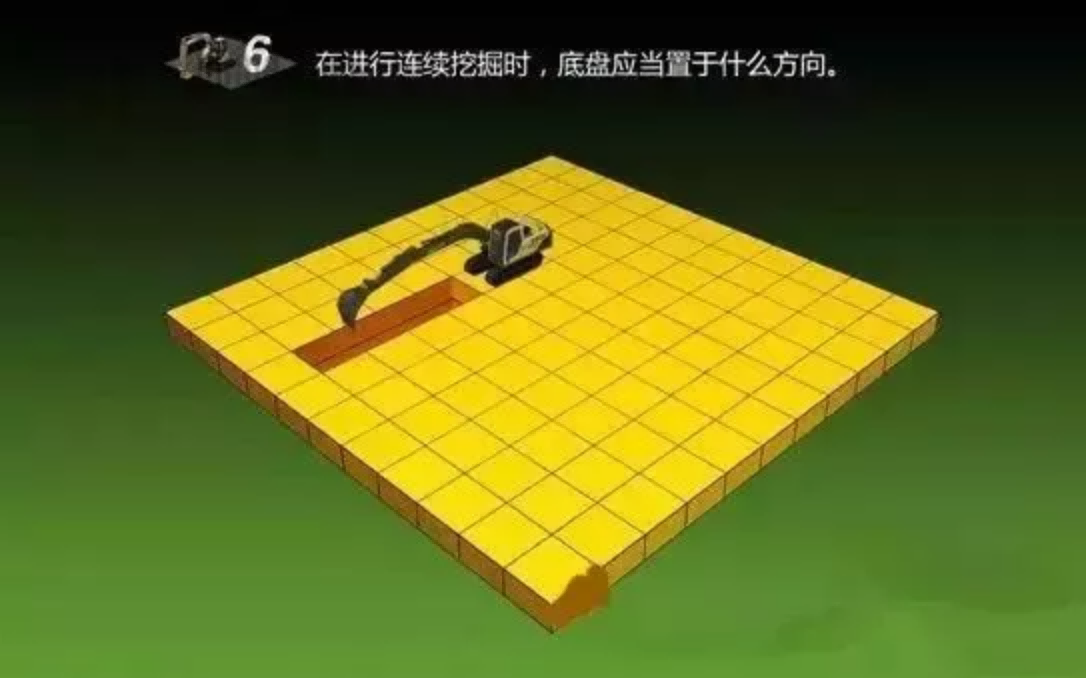

06

When carrying out continuous excavation, position the chassis in the forward direction so that it can start moving immediately after the excavation is completed. If you have to change the position of the chassis before moving, it will consume a significant amount of fuel when starting the machine again.

07

When performing the ditch-digging operation, dig the two sides of the trench first, and then dig the middle part. By doing so, it can save a lot of trouble and effort when digging the middle part.

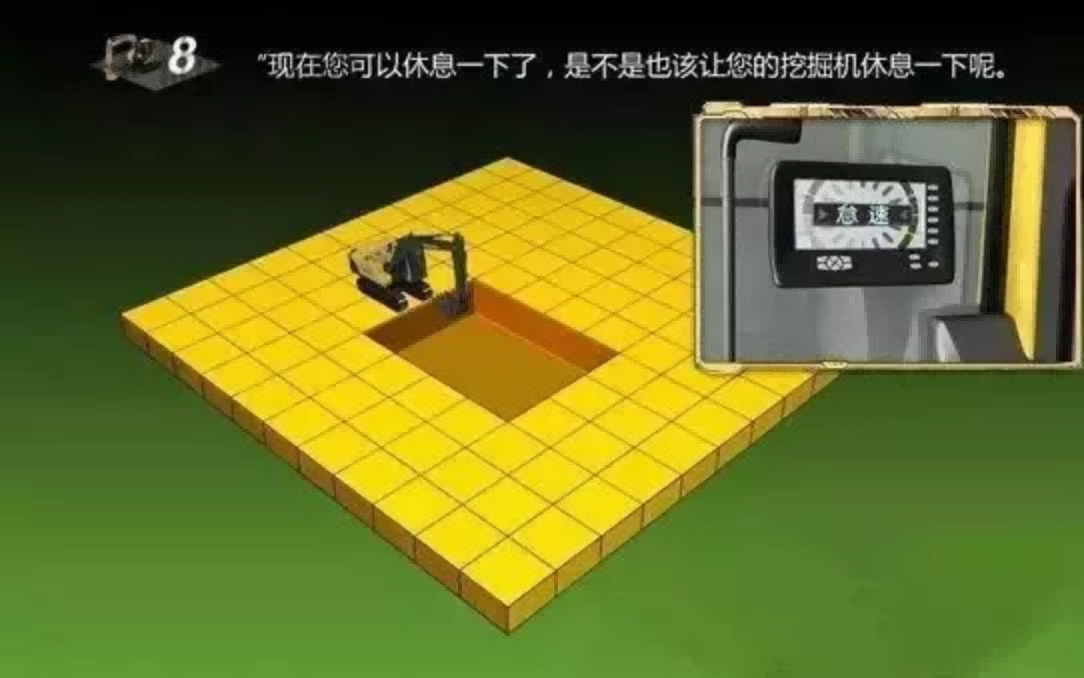

08

Set the engine throttle to the economic gear position. Select the automatic idling function and let the engine run at idle when the excavation stops.

09

Minimize the slewing radius.

10

The smaller the digging depth, the better the fuel economy during digging. It is advisable to adopt the segmented digging method. Divide the digging area into three layers: upper, middle and lower. If you dig from the bottom to the top in one go, firstly, the working range will be increased, and secondly, the power of the excavator will be reduced due to the increased range, which will reduce the work efficiency and consume a lot of fuel.

These small fuel-saving operation tips may not even be noticed by experienced operators in their daily work. However, as long as one can develop good operating habits, over time, it is indeed possible to save a considerable amount of fuel costs.