47 Ton Crawler Excavator

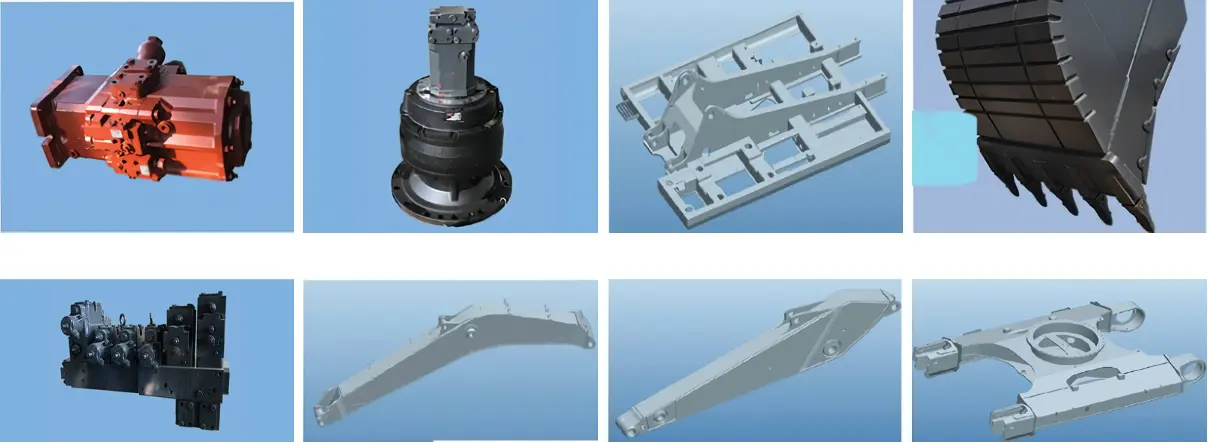

The 47-ton crawler excavator is a powerful and fuel-efficient heavy-duty construction machine. Its short-arm bucket configuration delivers exceptional digging force that outperforms other models in its class. Combined with faster swing speed, it significantly improves work efficiency. Equipped with a large-capacity fuel tank and advanced fuel-saving technology, it enables extended continuous operation and easily tackles various high-intensity construction tasks.

The SH470 crawler excavator is equipped with an advanced electro-hydraulic control system and a 5.7-inch high-resolution large-screen LCD display. This display screen features higher brightness and resolution, supports dynamic image display, and presents the overall operation information of the machine more comprehensively and intuitively. Key data is refreshed in real time to achieve continuous monitoring of the equipment's operating status. The engine ECU communicates with the controller via the CAN-BUS bus, which not only enhances the accuracy of power control but also realizes more efficient and comprehensive data acquisition, thereby significantly improving the overall operational efficiency of the machine. With the aid of advanced manufacturing techniques, this product features outstanding protective performance, ensuring stable and reliable operation even under harsh working conditions.

Product parameter:

Model | Unit | Parameter |

Engine | ||

Model | Cummins QSM11 | |

Form | 6-cylinder, inline, supercharged, intercooled | |

Cylinder X Bore X Stroke | (mm) | 6X125X150 |

Displacement | (L) | 11 |

Rated Power | (kw/rpm) | 250/2000 |

Bucket | ||

Bucket Capacity | (m³) | 2.0-2.2 |

Bucket Width | (mm) | 1350-1530 |

Digging Power | ||

Bucket Lever Digging Power | (KN) | 236 |

Bucket Digging Power | (KN) | 290 |

Hydraulic System | ||

Hydraulic Pump Type | 2 variable piston pumps + 1 gear pump | |

Maximum Flow Rate | (L/min) | 2x360+27 |

Traveling Circuit Pressure | (MPa) | 31.4 |

Slewing Circuit Pressure | (MPa) | 28.4 |

System Pressure | (MPa) | 3.9 |

Walking System | ||

Traveling Motor | Axial Variable Piston Motors | |

Number of Track Plates | 2x49 | |

Traveling Speed | (km/h) | 3.2/5.3 |

Traction Force | (kN) | 330 |

Climbing Capacity | 70%(35°) | |

Number of Supporting Wheels | 2×8 | |

Number of Sprocket Wheels | 2×2 | |

Operating Weight and Ground Specific Pressure | ||

Operating Weight | (Kg) | 44900 |

Ground Specific Pressure | (KPa) | 80.2 |

Slewing System | ||

Slewing Speed | (r/min) | 9.3 |

Brake Type | Pressure relief, mechanical brake | |

Oil Capacity | ||

Fuel tank capacity | (L) | 650 |

Cooling System | (L) | 26 |

Engine oil volume | (L) | 37.8 |

Hydraulic tank filling volume/hydraulic system capacity | (L) | 350/406 |

Bucket type | ||

A Overall Length | (mm) | 12090 |

B Grounding Length (For Transportation) | (mm) | 6735 |

C Overall Height (To Top of Boom) | (mm) | 3590 |

D Overall Width | (mm) | 3490 |

E Overall Height (To Top of Cab) | (mm) | 3276 |

F Counterweight Ground Clearance | (mm) | 1321 |

G Minimum Ground Clearance | (mm) | 557 |

H Tail Swing Radius | (mm) | 3655 |

I Wheelbase | (mm) | 4290 |

J Track Length | (mm) | 5335 |

K Track Spacing | (mm) | 2760 |

L Track Width | (mm) | 3360 |

M Track Plate Width | (mm) | 600 |

O Hood Height | (mm) | 2815 |

P Rotary Table Width | (mm) | 3195 |

Q Distance From Swing Center to Rear End | (mm) | 3655 |

Boom Type | ||

A Maximum Digging Height | (mm) | 10924 |

B Maximum Unloading Height | (mm) | 7615 |

C Maximum Digging Depth | (mm) | 7800 |

D Maximum Vertical Digging Depth | (mm) | 7066 |

E Maximum Digging Depth When Digging Out 8 Feet of Horizontal Surface | (mm) | 7650 |

F Maximum Digging Distance | (mm) | 12016 |

G Maximum Digging Distance at Ground Level | (mm) | 11814 |

H Minimum Turning Radius of Work Unit | (mm) | 4825 |

In terms of control algorithms, SH470 adopts the multi-neural adaptive PDI algorithm as the core of fuzzy control. This intelligent algorithm automatically avoids the integration stage when the system error is large. When the error decreases, it intelligently introduces integration regulation, which can not only quickly eliminate the deviation and prevent integration saturation, but also accelerate the system regulation process. By enhancing the system's adaptive capability and improving the steady-state error, the equipment can simultaneously possess excellent static and dynamic performance, ultimately achieving online energy-saving control of excavators.

Company Strength:

Shandong Shitian Heavy Industry Co., Ltd. is located in the Technology Industrial Development Zone of Jining High-tech Zone, Shandong Province. It is a national high-tech enterprise with the right to import and export.

The company has 9 subsidiaries worldwide, and the factory covers an area of 120,000 square meters. There are 700 employees, including over 50 professional engineers and technicians, as well as senior engineers. The company is dedicated to the research and development, design and production of a full range of excavators, bulldozers and other construction machinery products. It is a leader in large-scale energy-saving mining machinery and micro electric machinery in China. The series of mining equipment and micro electric equipment it has developed are at the international leading level.

Its SH60-8, SH220-8, SH380-9, SH470-9, SH500-9, SH600-9 and other series of excavators are designed with advanced technologies and concepts from Japan and Germany. They have been verified for decades in mining, highway and quarry conditions and are renowned for their high efficiency and energy conservation. With a good international perspective and an outstanding team of product engineers, the company adheres to the core concepts of "reliability", "energy conservation" and "efficiency", and with the work style of "paying attention to details" and "striving for excellence", it maintains the advantages of solid product technology and high quality, and promotes the international development of its series of products.