50 Ton Large Hydraulic Excavator

This 50-ton large hydraulic excavator delivers powerful and efficient performance with exceptional economy. Its short-arm bucket provides industry-leading digging force in its class, enabling it to tackle tough materials with ease. Combined with faster swing speed, it significantly reduces each digging cycle time. Paired with a large-capacity fuel tank and outstanding fuel-saving design, a single refueling extends continuous operation by approximately 20%, directly lowering your operating costs and enhancing project profitability.

Product Description:

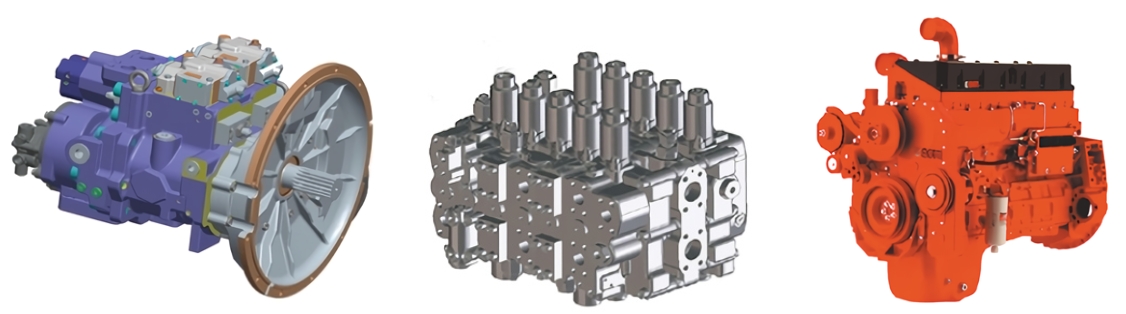

SH500-9 large hydraulic excavator using Cummins engine, with reliable, efficient, low fuel consumption advantages.

Engine power :280Kw, speed: 1850rpm

The electronic control of high pressure fuel injection is used to optimize fuel injection and reduce fuel consumption. Reduce fuel consumption and noise by reducing excess engine rotation in light operations with synchronous control.

Toshiba main valve

Toshiba main valve features

1, linear walking circuit; ,

2, boom priority, boom and bucket rod compound action priority;

3, rotation priority, rotation priority when the bucket rod rotation compound action; ,

4, bucket confluence, standby confluence loop;

5, bucket rod regeneration; ,

6, boom regeneration;

7, bucket rod, boom load holding valve.

Product parameter:

Model | Unit | Parameter |

Engine | ||

Model | Cummins QSM11 | |

Form | 6-cylinder, inline, supercharged, intercooled | |

Cylinder X Bore X Stroke | (mm) | 6X125X150 |

Displacement | (L) | 11 |

Rated Power | (kw/rpm) | 280/2000 |

Bucket | ||

Bucket Capacity | (m³) | 2.5-2.8 |

Bucket Width | (mm) | 1968 |

Digging Power | ||

Bucket Lever Digging Power | (KN) | 246 |

Bucket Digging Power | (KN) | 290 |

Hydraulic System | ||

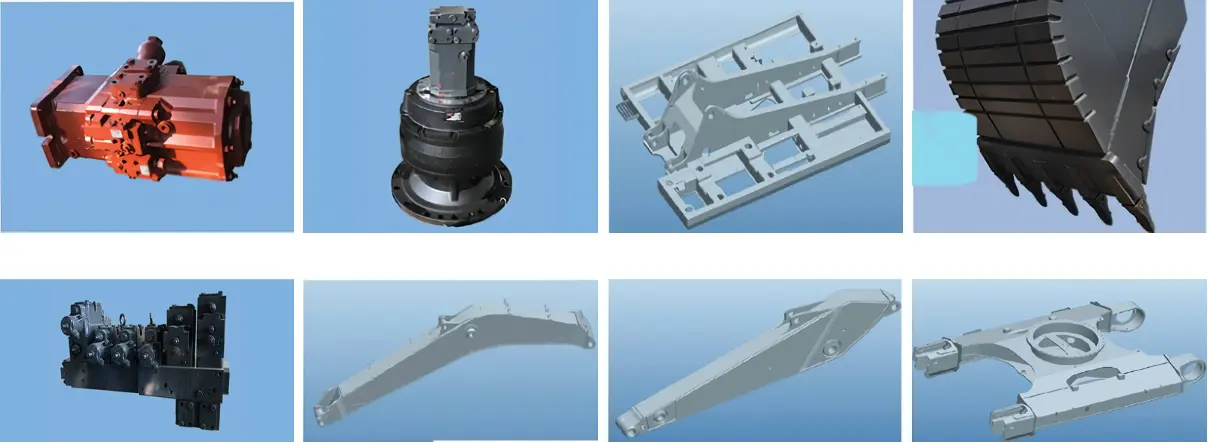

Hydraulic Pump Type | 2 variable piston pumps + 1 gear pump | |

Maximum Flow Rate | (L/min) | 2x385+27 |

Traveling Circuit Pressure | (MPa) | 34.3 |

Slewing Circuit Pressure | (MPa) | 28.4 |

System Pressure | (MPa) | 3.9 |

Walking System | ||

Traveling Motor | Axial Variable Piston Motors | |

Number of Track Plates | 2x49 | |

Traveling Speed | (km/h) | 3.2/5.3 |

Traction Force | (kN) | 330 |

Climbing Capacity | 70%(35°) | |

Number of Supporting Wheels | 2×8 | |

Number of Sprocket Wheels | 2×2 | |

Operating Weight and Ground Specific Pressure | ||

Operating Weight | (Kg) | 49600 |

Ground Specific Pressure | (KPa) | 81.9 |

Slewing System | ||

Slewing Speed | (r/min) | 9.3 |

Brake Type | Pressure relief, mechanical brake | |

Oil Capacity | ||

Fuel tank capacity | (L) | 650 |

Cooling System | (L) | 26 |

Engine oil volume | (L) | 37.8 |

Hydraulic tank filling volume/hydraulic system capacity | (L) | 350/450 |

Bucket type | ||

A Overall Length | (mm) | 12090 |

B Grounding Length (For Transportation) | (mm) | 6723 |

C Overall Height (To Top of Boom) | (mm) | 3590 |

D Overall Width | (mm) | 3490 |

E Overall Height (To Top of Cab) | (mm) | 3276 |

F Counterweight Ground Clearance | (mm) | 1321 |

G Minimum Ground Clearance | (mm) | 557 |

H Tail Swing Radius | (mm) | 3655 |

I Wheelbase | (mm) | 4290 |

J Track Length | (mm) | 5335 |

K Track Spacing | (mm) | 2760 |

L Track Width | (mm) | 3360 |

M Track Plate Width | (mm) | 600 |

O Hood Height | (mm) | 2815 |

P Rotary Table Width | (mm) | 3195 |

Q Distance From Swing Center to Rear End | (mm) | 3655 |

Boom Type | ||

A Maximum Digging Height | (mm) | 10924 |

B Maximum Unloading Height | (mm) | 7615 |

C Maximum Digging Depth | (mm) | 7800 |

D Maximum Vertical Digging Depth | (mm) | 7066 |

E Maximum Digging Depth When Digging Out 8 Feet of Horizontal Surface | (mm) | 7650 |

F Maximum Digging Distance | (mm) | 12016 |

G Maximum Digging Distance at Ground Level | (mm) | 11814 |

H Minimum Turning Radius of Work Unit | (mm) | 4825 |

Advanced electro-hydraulic system

With 5.7 inch large screen LCD LCD display, the machine information display is more comprehensive and intuitive, improve lumen and screen resolution, and provide dynamic images. Important information is displayed in real time, and the running status of the machine can be monitored in real time.

The engine ECU and the controller adopt CAN-BUS communication, the power control is more accurate, the data acquisition is more comprehensive and timely. The working efficiency of the whole machine is greatly improved. Advanced production process to ensure that the product has a high level of protection. Ensure the system can run stably and reliably under harsh working conditions.

The multi-neural derived adaptive PDI algorithm is adopted as the basic algorithm of fuzzy control. When the system error is large, the integral link is cancelled, and when the error is small, the integral link is introduced, which can quickly eliminate the error, avoid integral saturation, speed up the adjustment process, strengthen the system adaptability, and steady-state error, so that the static and dynamic performance indicators of the system are ideal, and the online energy saving control of the excavator is realized.

Company Strength:

Shandong Shitian Heavy Industry Co., Ltd. is located in the High-tech Industrial Development Zone of Jining City, Shandong Province. It is a national high-tech enterprise with import and export qualifications. The group has 9 subsidiaries worldwide, with a total production area of 120,000 square meters. It currently has over 700 employees, among whom more than 50 are professional technicians and senior engineers.

The company has long been dedicated to the research and development, design and manufacturing of a full range of excavators, bulldozers and other construction machinery. It is a benchmark enterprise in the field of large-scale energy-saving mining machinery and micro electric machinery in China. Its mining equipment and micro electric equipment series have entered the international leading ranks.

A variety of main models - including SH60-8, SH220-8, SH380-9, SH470-9, SH500-9, SH600-9, etc. - integrate advanced manufacturing techniques and design concepts from Japan and Germany. They have been strictly verified over many years in harsh working conditions such as mines, highways, and quarries. It has won wide trust with its outstanding energy-saving effect and stable performance.

Relying on a highly international perspective and a team of experienced engineers, the company has always adhered to the product concept of "reliability, energy conservation and efficiency", and the quality policy of "focusing on details and lean manufacturing". It constantly promotes the technological upgrading and quality improvement of its products, and helps Chinese construction machinery brands go global.

Why Choose Us:

1. We have an independent R&D team and cooperate with 3 large collaborative teams to develop and upgrade products. There are 8 core R&D members and 28 R&D and trial production staff.

2. Utilizing the international advanced TQc total quality management system to implement quality control management.

3. 21 senior technical service personnel to provide a full range of after-sales service.

4. Advanced production management team, industry management experience of more than 15 years, to ensure the assembly quality.