52 Ton Large Excavator

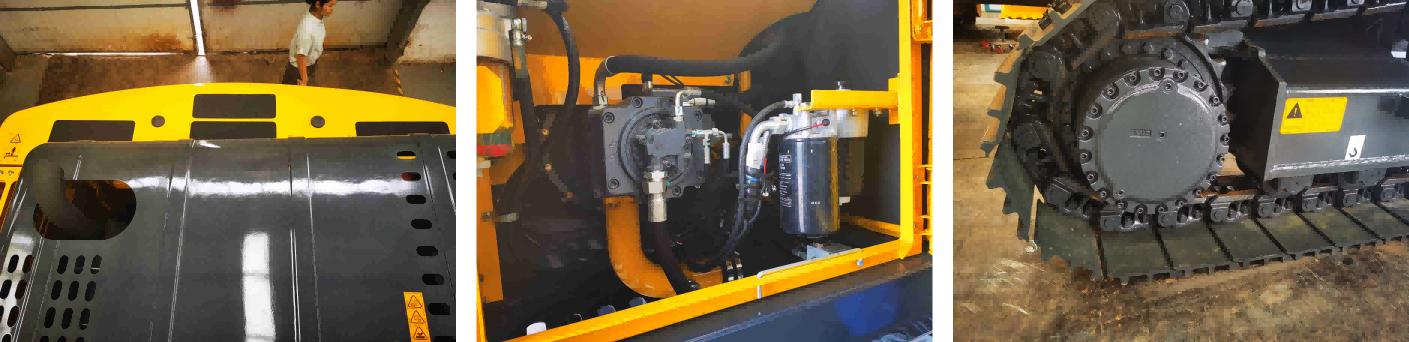

The 52-ton large excavator is a highly efficient and powerful heavy-duty machine. Its adjustable undercarriage design provides excellent stability during operation and makes transportation between sites much easier. Equipped with an upgraded hydraulic system, it delivers stronger digging force and faster swing speed than most models in its class, helping to complete tasks more quickly. With a large fuel tank and advanced fuel-saving technology, it can work longer without frequent refueling, making it ideal for demanding jobs like mining and major earthmoving projects.

Product description:

SH520-9 large excavator has the characteristics of more efficient, more energy saving and more environmental protection. Its excavator potential energy recovery technology was shortlisted in the national best energy saving technology and best energy saving practice announcement, and was approved 13 patents, becoming one of the best energy saving technologies in the field of construction machinery, opening a new era of energy conservation.

SH520-9 large excavator energy saving principle:

When the arm is falling, the oil in the large cavity of the arm enters the accumulator, and the energy is recovered and stored.

When the boom rises, the oil in the accumulator is converted into high-pressure oil and delivered to the boom cylinder, and the energy is released and utilized.

At this time, only one hydraulic main pump for the boom to rise, the other part of the flow is supplied from the accumulator, the conventional mode requires two main pumps at the same time to the boom cylinder oil supply.

Energy saving effect of SH520-9 large excavator:

The same tonnage saves 15%-20% of fuel consumption, and improves the comprehensive efficiency by 20%-30%.

Product parameter:

Model | Unit | Parameter |

Engine | ||

Model | Cummins QSM11 | |

Form | 6-cylinder, inline, supercharged, intercooled | |

Cylinder X Bore X Stroke | (mm) | 6X125X150 |

Displacement | (L) | 11 |

Rated Power | (kw/rpm) | 280/2000 |

Bucket | ||

Bucket Capacity | (m³) | 2.8-3.0 |

Bucket Width | (mm) | 1968 |

Digging Power | ||

Bucket Lever Digging Power | (KN) | 251 |

Bucket Digging Power | (KN) | 292 |

Hydraulic System | ||

Hydraulic Pump Type | 2 variable piston pumps + 1 gear pump | |

Maximum Flow Rate | (L/min) | 2x385+27 |

Traveling Circuit Pressure | (MPa) | 34.3 |

Slewing Circuit Pressure | (MPa) | 28.4 |

System Pressure | (MPa) | 3.9 |

Walking System | ||

Traveling Motor | Axial Variable Piston Motors | |

Number of Track Plates | 2x50 | |

Traveling Speed | (km/h) | 3.2/5.3 |

Traction Force | (kN) | 330 |

Climbing Capacity | 70%(35°) | |

Number of Supporting Wheels | 2×9 | |

Number of Sprocket Wheels | 2×2 | |

Operating Weight and Ground Specific Pressure | ||

Operating Weight | (Kg) | 50500 |

Ground Specific Pressure | (KPa) | 84 |

Slewing System | ||

Slewing Speed | (r/min) | 9.3 |

Brake Type | Pressure relief, mechanical brake | |

Oil Capacity | ||

Fuel tank capacity | (L) | 650 |

Cooling System | (L) | 39 |

Engine oil volume | (L) | 37.8 |

Hydraulic Tank System Capacity | (L) | 500 |

Bucket type | ||

A Overall Length | (mm) | 12545 |

B Grounding Length (For Transportation) | (mm) | 6733 |

C Overall Height (To Top of Boom) | (mm) | 3590 |

D Overall Width | (mm) | 3490 |

E Overall Height (To Top of Cab) | (mm) | 3286 |

F Counterweight Ground Clearance | (mm) | 1331 |

G Minimum Ground Clearance | (mm) | 696 |

H Tail Swing Radius | (mm) | 4110 |

I Wheelbase | (mm) | 4414 |

J Track Length | (mm) | 5480 |

K Track Spacing | (mm) | 2890/2392 |

L Track Width | (mm) | 3490/2992 |

M Track Plate Width | (mm) | 600 |

O Hood Height | (mm) | 2855 |

P Rotary Table Width | (mm) | 3322 |

Q Distance From Swing Center to Rear End | (mm) | 4110 |

Boom Type | ||

A Maximum Digging Height | (mm) | 11220 |

B Maximum Unloading Height | (mm) | 7814 |

C Maximum Digging Depth | (mm) | 7344 |

D Maximum Vertical Digging Depth | (mm) | 6502 |

E Maximum Digging Depth When Digging Out 8 Feet of Horizontal Surface | (mm) | 7192 |

F Maximum Digging Distance | (mm) | 11774 |

G Maximum Digging Distance at Ground Level | (mm) | 11552 |

H Minimum Turning Radius of Work Unit | (mm) | 4919 |

Company Strength:

Shandong Shitian Heavy Industry Co., Ltd. is located in the Technology Industrial Development Zone of Jining High-tech Zone, Shandong Province. It is a national high-tech enterprise with the right to import and export.

The company has 9 subsidiaries worldwide, and the factory covers an area of 120,000 square meters. There are 700 employees, including over 50 professional engineers and technicians, as well as senior engineers. The company is dedicated to the research and development, design and production of a full range of excavators, bulldozers and other construction machinery products. It is a leader in large-scale energy-saving mining machinery and micro electric machinery in China. The series of mining equipment and micro electric equipment it has developed are at the international leading level.

Its SH60-8, SH220-8, SH380-9, SH470-9, SH500-9, SH600-9 and other series of excavators are designed with advanced technologies and concepts from Japan and Germany. They have been verified for decades in mining, highway and quarry conditions and are renowned for their high efficiency and energy conservation. With a good international perspective and an outstanding team of product engineers, the company adheres to the core concepts of "reliability", "energy conservation" and "efficiency", and with the work style of "paying attention to details" and "striving for excellence", it maintains the advantages of solid product technology and high quality, and promotes the international development of its series of products.

Why Choose Us:

1.We not only have an independent R&D team, but also have established in-depth cooperation with three large-scale collaborative teams to continuously promote product development and technological upgrades. The team is led by 8 core R&D experts and staffed with 28 professional R&D and trial production personnel, jointly ensuring innovation capabilities and product implementation.

2.Comprehensively introduce the internationally advanced TQC (Total Quality Control) system to achieve refined quality control throughout the entire process from raw materials to finished products, ensuring that every link meets high standards.

3.Our team of 21 experienced technical service engineers provides customers with prompt, professional and reliable full-cycle after-sales support, effectively solving various problems during the usage process.

4.The production management team has an average of over 15 years of industry experience. With rich management accumulation and advanced assembly techniques, they strictly control product quality to ensure the stability and durability of equipment performance.