68 Ton Hydraulic Excavator

This 68-ton hydraulic excavator delivers outstanding overall performance. Its advanced turbocharged engine and positive flow hydraulic system provide powerful digging force while significantly reducing fuel consumption. The mining-grade reinforced chassis and wear-resistant bucket ensure reliable operation even under harsh working conditions. Additionally, the intelligent interactive display, low-noise cabin, and three-stage filtration system enhance operational precision, comfort, and reduced maintenance needs, comprehensively improving work efficiency.

Excellence drives, fear no limits

Equipped with a high-end custom high-power excavator engine, combined with a high-pressure common rail electronic fuel injection system and exclusive torque curve calibration, it delivers abundant and powerful output, easily handling the heavy-load working conditions in mines. The 68 ton hydraulic excavator can also adapt to the extreme environment at an altitude of 5,000 meters on the plateau, with reliable performance at all times.

Ultimate peace of mind and significant cost reduction

No post-treatment device, EGR system, or urea addition is required. The hydraulic excavator does not rely on low-sulfur fuel or high-grade engine oil, eliminating the need for regeneration during shutdown. This significantly reduces additional costs and time consumption, making operation and maintenance simpler and more economical.

High efficiency and energy conservation, precise consumption control

The Jinxin hydraulic system, combined with the fully electronically controlled positive flow technology, and supplemented by comprehensive optimization of flow channels and joints, achieves a 15% reduction in fuel consumption compared to similar products under the same operating efficiency. The engine has undergone all-round directional calibration and coordinated matching, significantly improving its energy consumption performance.

Strong mining leads to a significant increase in efficiency

The hinge points of the working device have been specially optimized for loading conditions, making the excavation trajectory more reasonable, with less resistance and smoother entry. The adoption of new materials for bucket teeth, bucket tooth seats and protective tooth structures has enhanced the wear resistance by 15%. The inclined knife plate design further strengthens the cutting force and feeding efficiency, significantly improving the overall operational efficiency.

Intelligent power regulation and dynamic matching for energy conservation

The system can automatically identify the working conditions and achieve precise power segmented control. Based on real-time gear and engine speed, it is dynamically matched to the optimal fuel economy range, precisely balancing the engine output and the power demand of the hydraulic pump, achieving both high efficiency and energy conservation.

Product parameters:

Model | Unit | Parameter |

Engine | ||

Model | WP15H | |

Form | Direct injection, water-cooled, four-stroke, supercharged, intercooled | |

Displacement | (L) | 15.33 |

Rated Power | (kw/rpm) | 566/1900 |

Bucket | ||

Bucket Capacity | (m³) | 3.6~4.5 |

Digging Power | ||

Bucket Lever Digging Power | (KN) | 350 |

Bucket Digging Power | (KN) | 420 |

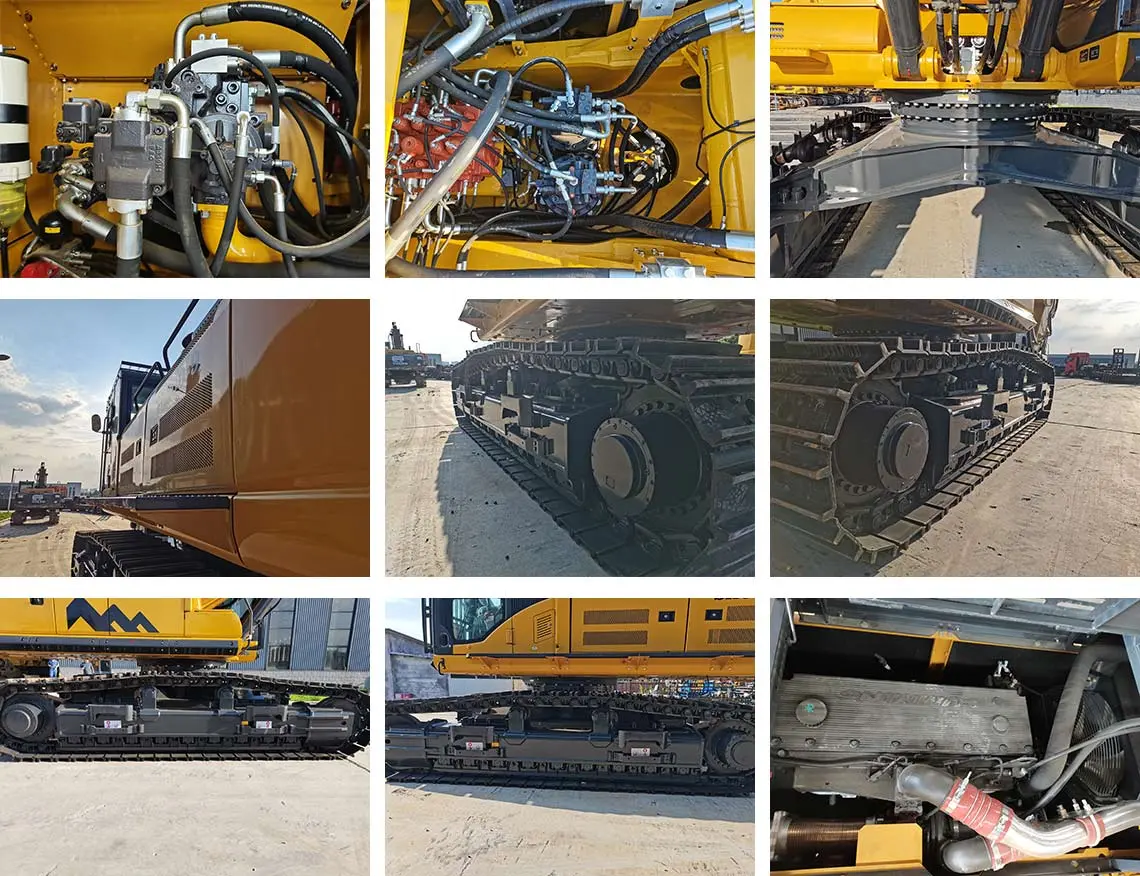

Hydraulic System | ||

Hydraulic Pump Type | 2 plunger pumps + gear pumps | |

Maximum Flow Rate | (L/min) | 2x510 |

Walking System | ||

Traveling Speed | (km/h) | 0-3.2-4.7 |

Traction Force | (kN) | 475 |

Climbing Capacity | 70%(35°) | |

Operating Weight and Ground Specific Pressure | ||

Operating Weight | (Kg) | 66000~69000 |

Ground Specific Pressure | (KPa) | 102 |

Slewing System | ||

Slewing Speed | (r/min) | 7 |

Brake Type | Pressure relief, mechanical braking | |

Oil Capacity | ||

Fuel tank capacity | (L) | 940 |

Cooling System | (L) | 76 |

Engine oil volume | (L) | 58 |

Hydraulic tank filling volume/hydraulic system capacity | (L) | 360/600 |

Bucket type | ||

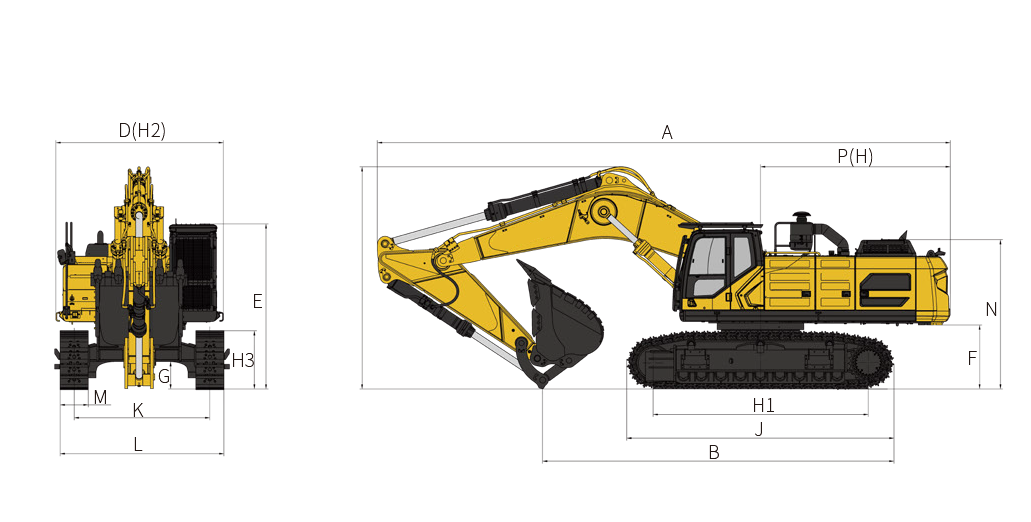

A Overall Length | (mm) | 12245 |

B Grounding Length (For Transportation) | (mm) | 7510 |

C Overall Height (To Top of Boom) | (mm) | 4750 |

D Overall Width | (mm) | 3735 |

E Overall Height (To Top of Cab) | (mm) | 3530 |

F Counterweight Ground Clearance | (mm) | 1370 |

G Minimum Ground Clearance | (mm) | 587 |

H Tail Swing Radius | (mm) | 4145 |

I Wheelbase | (mm) | 5710 |

J Track Length | (mm) | 2900 |

K Track Spacing | (mm) | 2760 |

L Track Width | (mm) | 3500 |

M Track Plate Width | (mm) | 600 |

P Rotary Table Width | (mm) | 3580 |

Q Distance From Swing Center to Rear End | (mm) | 4055 |

Boom Type | ||

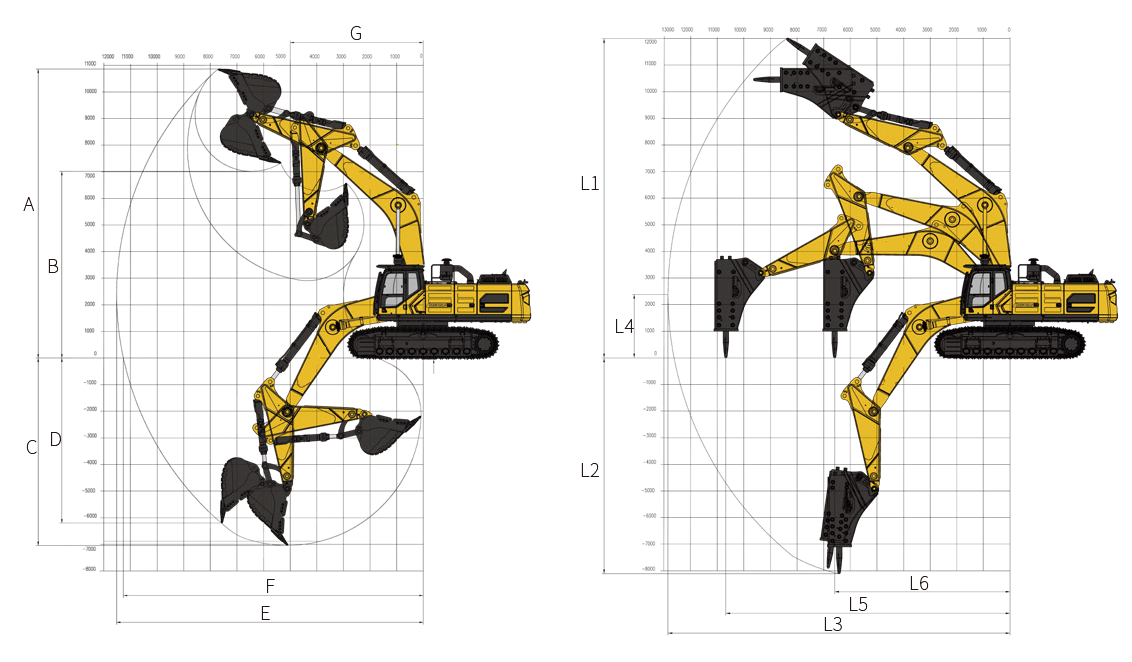

A Maximum Digging Height | (mm) | 10855 |

B Maximum Unloading Height | (mm) | 7015 |

C Maximum Digging Depth | (mm) | 7040 |

D Maximum Vertical Digging Depth | (mm) | 6195 |

E Maximum Digging Depth When Digging Out 8 Feet of Horizontal Surface | (mm) | 7650 |

F Maximum Digging Distance | (mm) | 11520 |

G Maximum Digging Distance at Ground Level | (mm) | 11250 |

H Minimum Turning Radius of Work Unit | (mm) | 5000 |

Collaborative optimization of hydraulics and power

The large-displacement main pump is highly matched with the engine, and the flow distribution of the main valve has been systematically optimized, making the compound actions more stable and the performance more outstanding. Equipped with high-torque rotary motors and walking motors, it provides strong rotary force and driving force, adapting to heavy-load working conditions and complex terrains.

The hydraulic control has been upgraded again

Through the optimization of the valve core structure, the innovation of the regeneration loop and the upgrade of the control strategy, the system pressure loss has been significantly reduced, and the overall control coordination and response accuracy have been further enhanced, achieving a perfect unity of precise operation and efficient output.

Five reasons to choose us

Professional research and development, collaborative innovation

1.We have established an independent R&D system and formed strategic cooperative relationships with three leading institutions in the industry, continuously conducting technological breakthroughs and product upgrades. The team consists of 8 core R&D experts and 28 R&D trial production specialists, achieving full-process technical coverage from concept to mass production.

2. International standards, outstanding quality

Comprehensively implement the TQC (Total Quality Control) system, build a full-chain refined control system from design to manufacturing, and ensure the reliability and consistency of products with high standards of quality requirements.

3. Technical support, full-process service

A professional support team composed of 21 senior technical service engineers provides comprehensive after-sales support including 7× 24-hour rapid response, regular inspection, fault early warning and remote diagnosis, ensuring that the equipment is always in the best condition.

4. Experience empowerment, precision manufacturing

The production management team has an average of over 15 years of industry experience. They deeply integrate advanced management concepts and process standards, strictly control the assembly quality of every link, and achieve a dual improvement in product performance and durability.

5. Continuous win-win, value co-creation

We attach great importance to establishing long-term cooperative relationships with our clients. Through continuous technological innovation, lean manufacturing and full life-cycle services, we provide our clients with better investment returns and sustainable value.

Certificates:

FAQ:

1.What products does the company mainly produce?

We focus on the research and development, design and production of a full range of excavators, bulldozers and other construction machinery, and are a leading enterprise in the field of large-scale energy-saving mining machinery and micro electric machinery in China. Our mining equipment and micro electric products have reached the international advanced level in technology and can provide customized solutions based on the specific needs of customers.

2. What are the payment methods?

The payment terms we usually accept are as follows: 30% of the total order amount should be prepaid as a deposit after the contract is signed, and the remaining 70% of the payment should be settled before the goods are dispatched.

3. How long is the delivery cycle?

The standard delivery time is 30 to 45 days after receiving the deposit. Inventory products can be dispatched immediately, while custom orders may require additional delivery time, depending on the specifications.

4. Which transportation methods are supported?

We offer flexible and diverse logistics solutions, covering various routes such as road, sea and air transportation. Most of the equipment can be transported by container or bulk cargo to ensure safe and efficient delivery.