80 Ton Hydraulic Excavator

The SD80 is a fully-featured large hydraulic excavator. Its customized hydraulic system ensures stable and efficient performance under heavy loads, while mining-grade tracks and large-capacity buckets deliver exceptional durability. The smart large screen supports personalized operation, and the spacious, low-noise cabin enhances comfort. The multi-stage filtration system significantly simplifies maintenance, ensuring high equipment availability and long-term operational reliability.

80 Ton Hydraulic Excavator Product Description

The 80 Ton Hydraulic Excavator is crafted with meticulous precision, delivering both high efficiency and energy - saving capabilities. It is outfitted with an engine that makes use of a customized torque curve and holds the distinction of having the largest displacement within the main pump industry. The optimization of the engine - hydraulic system synergy guarantees a consistent and potent output, even when subjected to heavy loads and operating at low speeds.

Engineered for long - lasting durability, this excavator showcases a robust construction. It features a four - wheel belt, a mining - grade working device, and a large - capacity, wear - resistant bucket. Such heavy - duty components render it highly reliable for arduous tasks, ensuring enduring performance in challenging working environments.

Technologically sophisticated, the excavator incorporates a 10.1 - inch human - computer interactive intelligent display. This display can adapt to diverse working conditions and allows for self - customized operation, thereby providing operators with enhanced flexibility and user - friendliness.

In terms of safety and comfort, the excavator comes equipped with a standard air suspension seat, creating a spacious and comfortable cabin. The low vibration and noise levels contribute to a pleasant driving experience, effectively reducing operator fatigue.

Maintenance of this excavator is straightforward and efficient. It is equipped with a three - level diesel filter and a standard oil bath - type air filter. These features simplify maintenance procedures, ensuring optimal performance with minimal downtime.

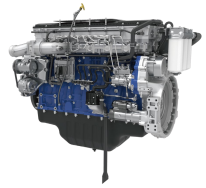

Engine Details

Model: WP17T

Displacement: 16.72L

Emission Certification: Country 4

Weichai + Linde Super Gold Hydraulic Combination

The 80 - Ton Hydraulic Excavator is equipped with a Weichai + Linde super gold combination, which features a high degree of matching. Leveraging advanced programming technology, it incorporates a full - electronic hydraulic system. This system offers a fast response speed, enabling more precise control over the excavator's operations.

Strong Drive

Powered by the Weichai WP17T high - power engine, this excavator benefits from a highly adaptable turbocharged engine. It operates at low speeds yet generates a large torque, providing robust power. In fact, its power output is 40% superior to that of competing products, with rapid response capabilities. This makes it an ideal choice for high - intensity mining operations.

Low Fuel Consumption

The fuel injection mode has been optimized, with a significant optimization of the fuel consumption curve. This expansion of the economic fuel consumption zone results in lower fuel consumption, achieving a 15% savings compared to competing products.

Cost Reduction

This excavator is designed without the need for post - processing. It does not require EGR (Exhaust Gas Recirculation), urea, low - sulfur fuel, or high - grade oil. Moreover, there is no downtime for regeneration, eliminating the associated time - cost of downtime regeneration.

Optimized Hinge Points of the Working Device

The key joints of the working device are fitted with self - lubricating copper - base alloy sleeves. These sleeves are highly wear - resistant, effectively reducing wear and tear. By optimizing the hinge points of the working device, the bucket's mining track is ensured, reducing mining resistance. As a result, the mining force is 9.7% stronger than that of competing products.

Strong Digging Power

In line with loading operations, the position of the hinged point of the working device has been optimized. This ensures the bucket's excavation track, reduces excavation resistance, and enhances working efficiency. The new - material bucket tooth, bucket tooth holder, and tooth guard offer 15% more abrasion resistance. The bevel main cutter plate is more conducive to cutting, with a 10% increase in cutting force, further improving work efficiency.

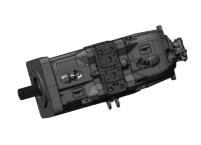

Hydraulic combination

HPR300 large displacement main pump, 7% better than competing products, greater output torque. Linde OCV36E main valve, full electronic control system, spool to achieve independent control, better handling. Linde HMF180 rotary motor with strong starting torque and smooth braking. KYB walking motor, low failure rate, walking traction is 10% better than competing products.

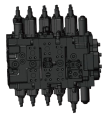

Fully electronically controlled positive flow hydraulic system

Fully electronically controlled positive flow hydraulic system, to achieve the perfect combination of load and flow, greatly improve the response speed. The electric control method realizes the relative rotation priority of the boom, the rotation priority of the bucket rod, the boom priority of the bucket rod, and the combination of the bucket, etc., cancelling the priority logic valve and reducing the pressure loss.

FAQ:

1.What products does the company mainly produce?

We focus on the research and development, design and production of a full range of excavators, bulldozers and other construction machinery, and are a leading enterprise in the field of large-scale energy-saving mining machinery and micro electric machinery in China. Our mining equipment and micro electric products have reached the international advanced level in technology and can provide customized solutions based on the specific needs of customers.

2. What are the payment methods?

The payment terms we usually accept are as follows: 30% of the total order amount should be prepaid as a deposit after the contract is signed, and the remaining 70% of the payment should be settled before the goods are dispatched.

3. How long is the delivery cycle?

The standard delivery time is 30 to 45 days after receiving the deposit. Inventory products can be dispatched immediately, while custom orders may require additional delivery time, depending on the specifications.

4. Which transportation methods are supported?

We offer flexible and diverse logistics solutions, covering various routes such as road, sea and air transportation. Most of the equipment can be transported by container or bulk cargo to ensure safe and efficient delivery.