610 HP Hydraulic Crawler Bulldozer

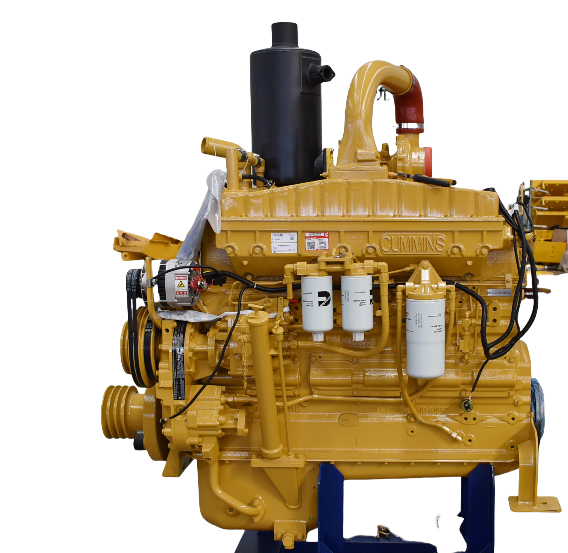

QSK19 electronic control engine carried by crawler bulldozer has outstanding advantages. Its electronic control system accurately regulates fuel injection, saves fuel under light load, and relies on the strong power of turbocharged generate under heavy load; The structure is reliable, and the key components are made of high-quality materials, which reduces the failure; Advanced modular design simplifies assembly and maintenance; Also relying on the global service network, remote guidance or on-site maintenance can be provided. Adapting to complex operations as a whole, giving consideration to efficiency and economy, and escorting the stable operation of equipment.

Shanbo SD60 bulldozer is carefully configured on the core power and transmission system, which provides a strong guarantee for complex operations. It is equipped with QSK19 electronic control engine, which realizes precise control of fuel injection by means of electronic control system, reduces oil consumption during light-load operation, and relies on turbocharging technology to achieve fast and strong power in generate under heavy-load operation, so it can easily meet high-intensity demands such as hard soil pushing and gravel shoveling. At the same time, the key components of the engine are made of high-quality materials, which has strong structural reliability and greatly reduces the failure probability; Advanced modular design simplifies the assembly process, and the module can be disassembled and replaced separately in the later maintenance, saving time and cost. With the support of global service network, we can get remote guidance or on-site maintenance service in time no matter where the work place is, so as to ensure the continuous operation of the equipment.

In terms of transmission system, the SD60 bulldozer of Shanbo adopts hydraulic torque converter with locking function, which has excellent load adaptability. Its output torque can be dynamically adjusted with the working load. When facing materials with different hardness or slopes, it can automatically adapt to the resistance without frequent manual adjustment, so as to avoid power waste or equipment overload. When working at low speed (such as fine leveling and shovel loading at close range), hydraulic transmission is used to ensure smooth power transmission and more stable operation; When driving at high speed (such as long-distance transition), it automatically switches to mechanical transmission, reducing power loss, saving 10%-15% fuel compared with traditional transmission, obviously improving fuel economy and reducing long-term operation cost for users.

Shanbo Company is well aware of the importance of after-sales support to the long-term stable operation of equipment, and has built a perfect after-sales support system for this purpose. In terms of spare parts supply, the company has set up a professional spare parts warehouse, storing all kinds of spare parts of hydraulic transmission series bulldozers from core components (such as engine modules and hydraulic cylinders) to wearing parts (such as seals and filter elements), so as to ensure that customers do not have to wait for spare parts procurement for a long time during equipment maintenance and repair, and can obtain the required spare parts in time, greatly shortening the equipment downtime. At the same time, reasonably distributed service centers can rapidly allocate spare parts, and combined with efficient logistics and distribution, the supply efficiency of spare parts can be further improved, especially for special operation scenes such as remote mining areas and field sites, and spare parts can be delivered in time through emergency distribution channels.

In terms of service team configuration, Shanbo Company has set up a professional customer service team composed of senior engineers and technicians. Team members have many years' experience in construction machinery repair and maintenance, are familiar with the structural principle and troubleshooting methods of hydraulic transmission series bulldozers, and can quickly locate equipment problems through online remote diagnosis (such as video guidance and data monitoring) to provide customers with immediate technical support; For complex faults, engineers will bring special testing tools and spare parts to the site to carry out maintenance services efficiently. In addition, the team will regularly provide customers with equipment maintenance training, guide operators to standardize the use and daily maintenance, reduce equipment failures from the source, and ensure the operating efficiency of customers' equipment in all directions.