460 HP Large Bulldozer

SD46-6 crawler bulldozer adopts working device controlled by PPC pilot proportional valve, K-suspension floating walking system, global intelligent service system, rollover protection and falling object protection device, which has the advantages of advanced structure, strong adaptability to working conditions and high working efficiency. It is especially suitable for working conditions such as earthwork mining and rock stripping in mining, construction and other projects.

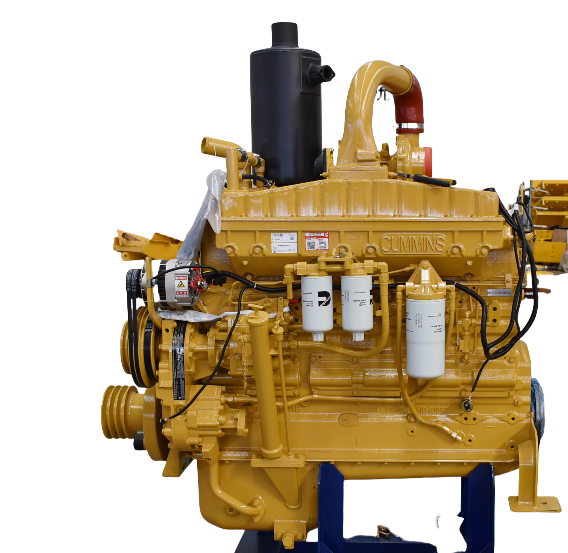

As a power unit specially designed for medium and large bulldozers, the power parameters of Cummins KTA19-C525 turbocharged diesel engine accurately match the working requirements of Shanbo SD46 bulldozer. With the help of turbocharging technology, the engine can explode strong torque in the low speed range, which is especially suitable for bulldozers in heavy-duty working conditions such as earth pushing, site leveling and hard soil peeling-whether it is pushing high-density clay, crushed gravel piles or driving on a steep working surface, the engine can maintain stable power output and avoid operation interruption caused by insufficient power.

At the same time, the engine adopts Cummins classic fuel injection system and combustion chamber optimization design, which makes the fuel atomization more complete and the combustion efficiency significantly improved compared with the ordinary diesel engine with the same power level. In the actual operation test of SD46 bulldozer in Shanbo, its fuel consumption is significantly lower than that of the same type bulldozer equipped with traditional engine under the same earthwork, which not only reduces the fuel cost of users, but also conforms to the current energy-saving and consumption-reducing trend in the field of construction machinery.

In view of the complicated working environment of bulldozers (often in contact with mud and dust) and the long-term vibration of equipment, Cummins KTA19-C525 engine adopts the integrated casting process of cylinder block and cylinder head, which completely abandons the design defect of relying on gasket connection in traditional split structure. The integrated structure not only greatly enhances the overall rigidity of the cylinder block and the cylinder head, but also can better withstand the high-frequency vibration and high temperature and high pressure when the engine is running, and also fundamentally eliminates the problems of water leakage and oil leakage caused by aging gaskets and loose bolts in the split structure.

In the reliability test of SD46 bulldozer in Shanbo, after the engine has been continuously operated for a long time (simulating harsh scenes such as mines and infrastructure), the disassembly inspection shows that there is no leakage trace on the joint surface of cylinder block and cylinder head, and the sealing performance of cooling system and lubricating system remains intact. This design not only reduces the downtime and maintenance times of bulldozer due to leakage fault, but also avoids the corrosion and wear of engine internal parts caused by coolant and engine oil leakage, and indirectly prolongs the service life of the engine.

Shanbo SD46 bulldozer's high-reliability power shift gearbox and planetary structure main reducer can transmit efficiently.

Its advantages are high power, high durability and high production efficiency.

● Automatically change the torque according to the change of external load, with high fuel economy.

● Hydraulic components can absorb the impact load of transmission device, which can increase the engine life by 1.5 ~ 2 times.

● The gearbox adopts multi-disc clutch, hydraulic combination and forced lubrication, and the central transmission adopts spiral bevel gear and splash lubrication.

Shanbo SD46 bulldozer innovatively designs the working valve as an external structure, completely solving the pain point of inconvenient maintenance of traditional built-in valves. The working valves of traditional bulldozers are mostly integrated inside the hydraulic oil tank or the machine body. During maintenance, a large number of surrounding components need to be disassembled, which takes a long time and is likely to cause secondary damage to adjacent components. However, the external working valve is independently installed on the side of the machine body through a modular design and is equipped with an exclusive protective cover. This design can not only prevent direct impact from soil and gravel during operation but also allow maintenance personnel to quickly access the main body of the valve by simply opening the protective cover without disassembling other components. Whether it is daily valve cleaning, pressure adjustment, or valve core replacement and seal maintenance in case of failures, the overall operation time is significantly shortened, which can effectively reduce the downtime for maintenance. It is particularly suitable for infrastructure and mining projects with tight construction schedules, helping users reduce construction delays caused by equipment maintenance and improve overall construction efficiency.