36 Tons Crawler Excavator

The 36-ton crawler excavator is a powerful, efficient, and reliable heavy-duty engineering equipment. Powered by a high-performance engine, it delivers superior power output compared to its peers, making it ideal for heavy-duty applications such as mining and rock excavation. Equipped with a large-capacity bucket and excellent digging force, it ensures high loading efficiency and significantly shorter work cycles. With precise control and outstanding fuel economy, it is the perfect choice for large-scale earthmoving and rock engineering projects.

36-Ton Crawler Excavator丨Professional High-Efficiency Operation Solution

Power System – High Performance, Low Energy Consumption

Equipped with a Japan-original Isuzu 6HK1X electronically controlled high-pressure common rail engine, rated at 212kW/2000rpm. It features intelligent electronic fuel injection and turbocharged intercooling technology, delivering high torque at low speeds (max torque ≥1060N·m). It maintains uninterrupted power even under heavy-duty mining and rock excavation conditions, with fuel consumption 8%-10% lower than comparable models.

Working Device – Reinforced Structure, Efficient Operation

Includes a standard 1.62m³ rock reinforcement bucket made of NM400 wear-resistant steel plate with a dual-arc design, increasing digging force by 15% and achieving a fill factor of over 95%. The optimized hydraulic system flow distribution enhances compound action coordination, reducing work cycle time by 10%, making the 36 tons crawler excavator suitable for high-intensity continuous loading operations.

Core Technical Advantages

Intelligent Power Control System: Automatically adjusts power output based on load, achieving optimal balance between economy and efficiency.

Heavy-Duty Chassis Structure: X-type box frame + reinforced track frame, meeting anti-torsion vibration requirements in rugged working conditions.

Three-Stage Fuel Filtration System: Ensures engine reliability and durability in harsh operating environments.

Applicable Working Conditions

Ideal for heavy-duty applications such as open-pit mining, large earthmoving projects, post-blast rock handling, and infrastructure construction.

A Benchmark in Energy Efficiency Among 36-Ton Products – Defining Reliability with Heavy-Duty Performance, Achieving Economy Through Intelligent Control!

Product parameters:

Model | Unit | Parameter |

Engine | ||

Model | Isuzu 6HKIX | |

Form | 6-cylinder, inline, supercharged, intercooled | |

Cylinder X Bore X Stroke | (mm) | 6X115X125 |

Displacement | (L) | 7.79 |

Rated Power | (kw/rpm) | 212/2000 |

Bucket | ||

Bucket Capacity | (m³) | 1.62 |

Bucket Width | (mm) | 1571 |

Digging Power | ||

Bucket Lever Digging Power | (KN) | 190 |

Bucket Digging Power | (KN) | 230 |

Hydraulic System | ||

Hydraulic Pump Type | 2 variable piston pumps + 1 gear pump | |

Maximum Flow Rate | (L/min) | 2×330 |

Traveling Circuit Pressure | (MPa) | 36 |

Slewing Circuit Pressure | (MPa) | 25.5 |

System Pressure | (MPa) | 36 |

Walking System | ||

Traveling Motor | Axial Variable Piston Motors | |

Number of Track Plates | 2x49 | |

Traveling Speed | (km/h) | 5.0/3.0 |

Traction Force | (kN) | 280 |

Climbing Capacity | 70%(35°) | |

Number of Supporting Wheels | 2×8 | |

Number of Sprocket Wheels | 2×2 | |

Operating Weight and Ground Specific Pressure | ||

Operating Weight | (Kg) | 35800 |

Ground Specific Pressure | (KPa) | 62 |

Slewing System | ||

Slewing Speed | (r/min) | 9.7 |

Brake Type | Pressure relief, mechanical brake | |

Oil Capacity | ||

Fuel tank capacity | (L) | 580 |

Cooling System | (L) | 32.5 |

Engine oil volume | (L) | 33 |

Hydraulic tank filling volume/hydraulic system capacity | (L) | 380/450 |

Bucket Type | ||

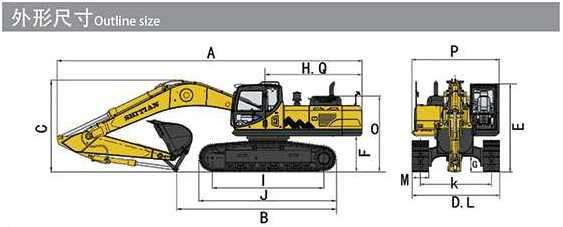

A Overall Length | (mm) | 11161 |

B Grounding Length (For Transportation) | (mm) | 5872 |

C Overall Height (To Top of Boom) | (mm) | 3347 |

D Overall Width | (mm) | 3200 |

E Overall Height (To Top of Cab) | (mm) | 3293 |

F Counterweight Ground Clearance | (mm) | 1312 |

G Minimum Ground Clearance | (mm) | 565 |

H Tail Swing Radius | (mm) | 3438 |

I Wheelbase | (mm) | 4080 |

J Track Length | (mm) | 5044 |

K Track Spacing | (mm) | 2600 |

L Track Width | (mm) | 3200 |

M Track Plate Width | (mm) | 600 |

O Hood Height | (mm) | 2421 |

P Rotary Table Width | (mm) | 3195.3 |

Q Distance From Swing Center to Rear End | (mm) | 3438 |

Boom Type | ||

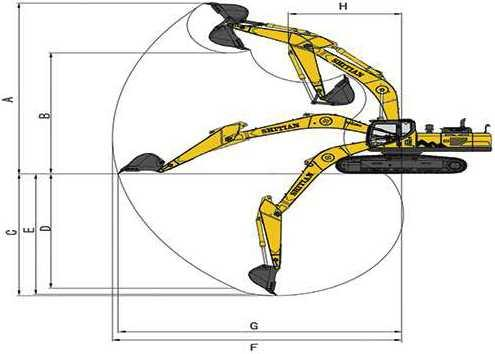

A Maximum Digging Height | (mm) | 10134 |

B Maximum Unloading Height | (mm) | 7182 |

C Maximum Digging Depth | (mm) | 7240 |

D Maximum Vertical Digging Depth | (mm) | 7170.5 |

E Maximum Digging Depth When Digging Out 8 Feet of Horizontal Surface | (mm) | 6812.5 |

F Maximum Digging Distance | (mm) | 11051 |

G Maximum Digging Distance at Ground Level | (mm) | 10839 |

H Minimum Turning Radius of Work Unit | (mm) | 4332 |

Company Strength:

Shandong Shitian Heavy Industry Co., Ltd (Jining Shan re-energy) is located in Jining City, Shandong Province, high-tech zone technology industrial development zone. It is a high-tech enterprise specializing in the research, development and production of large excavators. For the large energy-saving excavator design, research and development and production of the leader, the development of hybrid large excavator SH520-9 energy-saving effect reached more than 30%.

In 2020, Jining Shan re-energy hybrid excavator production base project into the key support projects in Shandong Province, its conventional products SH380-9 using a full set of German Linde hydraulic system, strong digging performance, upholding the German industrial products, reliable and efficient design and manufacturing concepts; SH470-9, SH500-9, SH600 in the mines, highways, quarry conditions after decades of verification, known for high efficiency, energy saving The SH470-9, SH500-9, SH600 have been proven in mining, highway and quarry conditions for decades and are famous for high efficiency and energy saving.

Why Choose Us:

1. We have an independent R&D team and cooperate with 3 large collaborative teams to develop and upgrade products. There are 8 core R&D members and 28 R&D and trial production staff.

2. Utilizing the international advanced TQc total quality management system to implement quality control management.

3. 21 senior technical service personnel to provide a full range of after-sales service.

4. Advanced production management team, industry management experience of more than 15 years, to ensure the assembly quality.