260 HP Standard Medium Bulldozer

SD260 crawler bulldozer adopts advanced technologies such as hydraulic transmission, hydraulic control, electronic monitoring and large-capacity bulldozer, equipped with anti-rolling protection device, hexahedral cab with good vision, air conditioning system and ergonomically designed control system, with reasonable structure, advanced performance and simple operation.

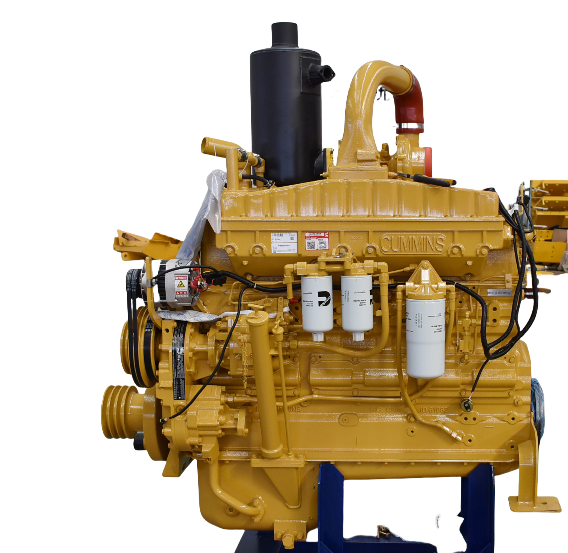

In terms of the core power system, the Shanbo SD26 bulldozer is equipped with a high-power Cummins NT855-C280S10 engine, matched with a customized high-efficiency turbocharger. This "golden power combination" not only significantly expands the engine's high-efficiency operating range — even under different working conditions such as low-speed heavy load and high-speed operation, the engine can always maintain the speed range with optimal fuel efficiency, effectively reducing power waste — but also significantly lowers fuel consumption. According to actual working condition tests, compared with conventional power models of the same level, its fuel consumption per 100 kilometers can be reduced by 8%-12%. Long-term use can greatly save operating costs for users while reducing carbon emissions, meeting the needs of green construction.

As the "skeleton" of the entire machine, the main frame adopts a full box-type closed structure design. Compared with the traditional open or semi-closed frame, this structure can evenly distribute the stress to the entire frame body, with the impact load resistance increased by more than 40%. It can effectively avoid deformation caused by local stress concentration when facing impacts such as stone collisions and ground bumps in complex working conditions like mines and infrastructure construction sites. At the same time, its bending and torsion resistance is also more excellent; even in scenarios such as operation on steep slopes or uneven stress on one side, the frame is not easy to twist and deform, ensuring the structural stability of the entire machine. In terms of materials and processes, the main frame is made of Q690 high-strength alloy steel, and high-strength cast steel parts are embedded in key load-bearing parts for reinforcement, making the overall structural strength 35% higher than that of frames made of ordinary steel. All welds adopt robotic automatic welding technology, with the welding depth reaching more than 80% of the base material thickness. Each weld is inspected by ultrasonic flaw detection to ensure no false welding or missing welding, fundamentally ensuring that the main frame has the same full-life cycle service life as the entire machine and effectively reducing the later maintenance and replacement costs.

In terms of working device configuration, the Shanbo SD26 bulldozer is equipped with a high-quality standard straight blade. The blade is made of NM450 wear-resistant steel, and the blade edge is inlaid with high-manganese steel wear-resistant strips. It not only has high overall structural strength, but also its wear resistance is more than twice that of ordinary blades. Facing complex materials such as hard soil and gravel, it can still maintain strong cutting force. Even under long-term high-intensity operation, the blade is not easy to be damaged such as edge curling and cracking. At the same time, to meet the needs of different construction scenarios, the manufacturer also provides users with an optional U-shaped blade. The U-shaped blade adopts a curved bottom design, with the material storage capacity 15% higher than that of the straight blade and smoother unloading. It is especially suitable for large-scale material handling operations such as earth transfer and site leveling, which can further improve work efficiency. In addition, the single-tooth scarifier equipped with the entire machine also has excellent performance. Its penetration angle can be steplessly adjusted from 0° to 30° through the hydraulic system, which can be flexibly adapted according to soil hardness (from soft loam to hard weathered rock). Combined with the high-strength alloy tooth tip, it has strong penetration capacity. Even in the face of relatively hard rock formations, it can easily crush and loosen them, clearing obstacles for subsequent dozing operations.

The cab design fully follows the principles of ergonomics to create a convenient and comfortable operating environment. Among them, the gear shift lever, steering control device and throttle adjustment components are scientifically centralized in the operating area on the driver's left side, all adopting a flexible shaft transmission structure. This structure not only has more sensitive transmission response and more uniform damping feeling during operation, which can effectively avoid the jamming problem of traditional hard rod transmission, but also reduces the operating force. Even during long-term continuous operation, the driver's left arm is not easy to feel fatigued. On the other hand, the control components of the bulldozer's working devices (such as dozing and scarifying) are centrally arranged on the driver's right side, equipped with a high-precision servo control system. Through the synergy of hydraulic power assistance and electronic sensing, this system can control the operation accuracy to the millimeter level. Whether fine-tuning the angle of the blade or accurately controlling the scarifying depth, it can achieve flexible operation like "moving as directed", greatly reducing the operation difficulty and improving construction efficiency and work quality.