38 Ton Crawler Hydraulic Excavator

The 38-ton crawler hydraulic excavator is equipped with the world-class Linde load-sensing hydraulic system and features the largest main pump capacity in its class. With higher working pressure and greater power output, it ensures exceptional digging force and operational stability, outperforming standard models in the same category.

SH380 - 9 Crawler Hydraulic Excavator Product Description

The 38 - Ton Crawler Hydraulic Excavator, specifically the SH380 - 9 model, offers a significant upgrade compared to the original product. It showcases a 15% increase in efficiency and a 10% reduction in fuel consumption.

This hydraulic excavator is equipped with an original imported Isuzu 6HKIX six - cylinder engine, a renowned international brand. Meeting the national three emission standard, the engine features excellent performance, energy - saving characteristics, and is easy to maintain.

The SH380 - 9 crawler hydraulic excavator boasts a powerful digging force. With a bucket digging force of 230KN and a bucket bar digging force of 190KN, it can handle tough excavation tasks with ease. Its slewing is agile, and the digging cycle time is shortened, with a slewing speed of 9.7r/min, leading the industry in this aspect.

Furthermore, it has a substantial extension of continuous operation time. Thanks to the use of a large - capacity fuel tank (a 580L fuel tank with excellent fuel - saving performance), the working time is extended by 20%. This enables the excavator to operate for longer periods without frequent refueling, enhancing overall productivity in various construction and excavation projects.

Product parameters:

Model | Unit | Parameter |

Engine | ||

Model | Cummins 6LTAA8.9 | |

Form | 6-cylinder, inline, supercharged, intercooled | |

Cylinder X Bore X Stroke | (mm) | 6X115X125 |

Displacement | (L) | 8.9 |

Rated Power | (kw/rpm) | 242/2100 |

Bucket | ||

Bucket Capacity | (m³) | 1.62-1.82 |

Bucket Width | (mm) | 1571 |

Digging Power | ||

Bucket Lever Digging Power | (KN) | 182 |

Bucket Digging Power | (KN) | 220 |

Hydraulic System | ||

Hydraulic Pump Type | 2 variable piston pumps + 1 gear pump | |

Maximum Flow Rate | (L/min) | 2×336 |

Traveling Circuit Pressure | (MPa) | 34.3 |

Slewing Circuit Pressure | (MPa) | 28.5 |

System Pressure | (MPa) | 34.3 |

Walking System | ||

Traveling Motor | Axial Variable Piston Motors | |

Number of Track Plates | 2x49 | |

Traveling Speed | (km/h) | 5.0/3.0 |

Traction Force | (kN) | 280 |

Climbing Capacity | 70%(35°) | |

Number of Supporting Wheels | 2×8 | |

Number of Sprocket Wheels | 2×2 | |

Operating Weight and Ground Specific Pressure | ||

Operating Weight | (Kg) | 37000 |

Ground Specific Pressure | (KPa) | 62 |

Slewing System | ||

Slewing Speed | (r/min) | 9.7 |

Brake Type | Pressure relief, mechanical brake | |

Oil Capacity | ||

Fuel tank capacity | (L) | 580 |

Cooling System | (L) | 32.5 |

Engine oil volume | (L) | 33 |

Hydraulic tank filling volume/hydraulic system capacity | (L) | 380/450 |

Bucket Type | ||

A Overall Length | (mm) | 11161 |

B Grounding Length (For Transportation) | (mm) | 5872 |

C Overall Height (To Top of Boom) | (mm) | 3347 |

D Overall Width | (mm) | 3200 |

E Overall Height (To Top of Cab) | (mm) | 3293 |

F Counterweight Ground Clearance | (mm) | 1312 |

G Minimum Ground Clearance | (mm) | 565 |

H Tail Swing Radius | (mm) | 3438 |

I Wheelbase | (mm) | 4080 |

J Track Length | (mm) | 5044 |

K Track Spacing | (mm) | 2600 |

L Track Width | (mm) | 3200 |

M Track Plate Width | (mm) | 600 |

O Hood Height | (mm) | 2421 |

P Rotary Table Width | (mm) | 3195.3 |

Q Distance From Swing Center to Rear End | (mm) | 3438 |

Boom Type | ||

A Maximum Digging Height | (mm) | 10134 |

B Maximum Unloading Height | (mm) | 7182 |

C Maximum Digging Depth | (mm) | 7240 |

D Maximum Vertical Digging Depth | (mm) | 7170.5 |

E Maximum Digging Depth When Digging Out 8 Feet of Horizontal Surface | (mm) | 6812.5 |

F Maximum Digging Distance | (mm) | 11051 |

G Maximum Digging Distance at Ground Level | (mm) | 10839 |

H Minimum Turning Radius of Work Unit | (mm) | 4332 |

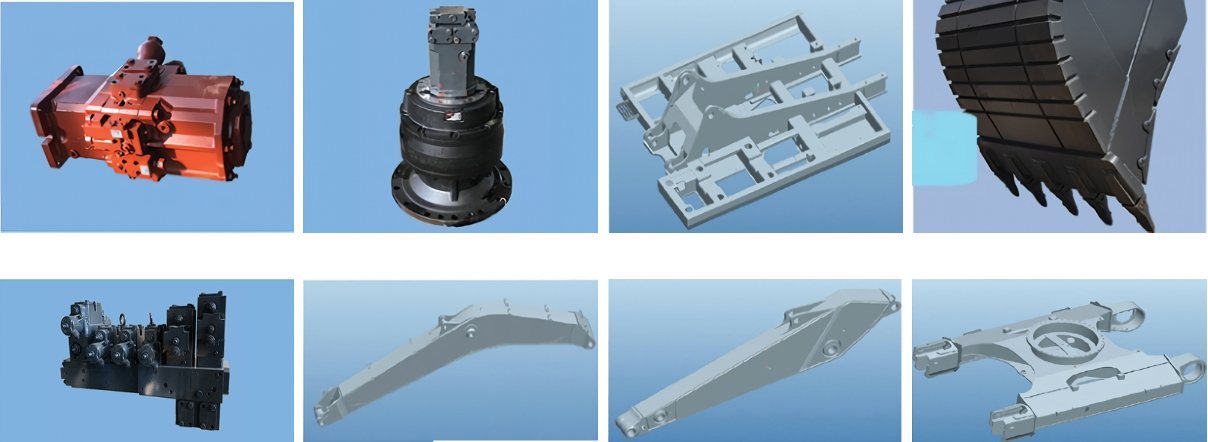

Product Details:

Linde Load Sensitive Pumps

Employing load - sensing control, it enables automatic power matching, ensuring optimal power utilization.

By supplying flow on an as - needed basis, it effectively reduces power loss, enhancing energy efficiency.

Exhibits excellent self - priming capabilities even at high rated speeds, facilitating smooth operation startup.

The noise level is optimized within the rated speed range, contributing to a quieter working environment.

With a working pressure of 36Mpa, it can reach up to 42Mpa, guaranteeing the most powerful digging force for handling tough excavation tasks.

Linde Rotary Motor

Demonstrates outstanding low - speed stability performance, allowing for precise and controlled movement.

Features a high starting torque, enabling it to initiate operations smoothly even under heavy loads.

Reduces noise by controlling the speed, creating a more comfortable working atmosphere.

Boasts a compact construction, saving space while maintaining high functionality.

Presents a high power - density ratio, delivering significant power output relative to its size.

Ensures high reliability, minimizing the risk of breakdowns during operation.

Has a long service life, providing long - term value for users.

Exhibits a fast dynamic response, quickly adapting to changes in operating conditions.

Incorporates a streamlined power transmission system, enhancing power transfer efficiency.

Load - sensitive Synchronized Control Valves

Utilizes pressure - compensated technology, ensuring smooth operation even in complex mining and construction environments.

Enables the full utilization of engine power, maximizing the excavator's performance.

Each actuator operates independently of one another, improving the coordination and operational efficiency of the machine.

The main valve has a built - in back - pressure valve and relief valve, simplifying the piping system and enhancing overall system efficiency.

Reinforced Arm

High - stress areas are constructed using high - tensile - strength steel plates, enhancing the arm's durability under heavy loads.

The shaft seat is made of forged parts, providing increased strength and reliability.

A large - cross - section spacer is welded to the center section, further strengthening the structure.

Reinforced Bucket Bar

Adopts a box - type large - cross - section structure, enhancing its strength and resistance to wear and tear during digging operations.

Reinforced Turntable

The "central load - bearing structure" of the upper rotary table distributes the force directly to the chassis through the upper structure. This reduces stress, improves durability, and extends the service life of the machine.

The use of a floating - seal - ring - type drag chain wheel prevents soil and sand from entering from the upper part of the drag chain wheel, ensuring the durability of the traveling mechanism.

Enhanced X - frame Structure Improves Quality

The reinforced design of the stress - concentrated beam structure increases the cross - sectional strength by more than 35% compared to conventional models. This makes it more adaptable to severe working conditions and heavy loads.

Reinforced Bucket

The wear - prone parts of the bucket (front, sides, and bottom) are reinforced with super - wear - resistant welded plates. As a result, the average service life of the bucket is more than 20% longer than that of traditional models.

Company Strength:

Shandong Shitian Heavy Industry Co., Ltd (Jining Shan re-energy) is located in Jining City, Shandong Province, high-tech zone technology industrial development zone. It is a high-tech enterprise specializing in the research, development and production of large excavators. For the large energy-saving excavator design, research and development and production of the leader, the development of hybrid large excavator SH520-9 energy-saving effect reached more than 30%.

In 2020, Jining Shan re-energy hybrid excavator production base project into the key support projects in Shandong Province, its conventional products SH380-9 using a full set of German Linde hydraulic system, strong digging performance, upholding the German industrial products, reliable and efficient design and manufacturing concepts; SH470-9, SH500-9, SH600 in the mines, highways, quarry conditions after decades of verification, known for high efficiency, energy saving The SH470-9, SH500-9, SH600 have been proven in mining, highway and quarry conditions for decades and are famous for high efficiency and energy saving.

Why Choose Us:

1. We have an independent R&D team and cooperate with 3 large collaborative teams to develop and upgrade products. There are 8 core R&D members and 28 R&D and trial production staff.

2. Utilizing the international advanced TQc total quality management system to implement quality control management.

3. 21 senior technical service personnel to provide a full range of after-sales service.

4. Advanced production management team, industry management experience of more than 15 years, to ensure the assembly quality.