22 Ton Crawler Excavator

This 22-ton crawler excavator is an efficient, energy-saving, and stable and reliable piece of engineering machinery. It adopts a reinforced structure and an intelligent hydraulic system, significantly increasing digging force by 11% and reducing fuel consumption by 5%-8%. Combined with its convenient maintenance design, it fully meets the demands of high-intensity operations.

Product description:

The SH220-8 hydraulic excavator is designed to provide operators with a safer and more comfortable working experience. It features a newly designed cab with excellent visibility and significantly reduced interior noise, creating a quieter and more comfortable operating environment. An optimized silicone oil damper effectively minimizes vibration, further enhancing operational comfort. The cab is also equipped with an imported high-performance air conditioning system and an integrated control panel, ensuring user-friendly operation and efficient temperature control.

The multi-directional adjustable seat can accommodate different body types and operating habits, effectively reducing fatigue during long hours of work. In terms of safety, the SH220-8 comes standard with a ROPS-compliant anti-rollover cab, greatly improving operator protection. Optional cab protective nets and anti-collision side beams are available to enhance operational safety in demanding working conditions such as mining.

Additionally, the internal and external air filter elements of this model are easy to remove and clean, helping to maintain high air quality inside the cab. The machine is also equipped with a negative battery switch, allowing for quick power disconnection to facilitate maintenance and long-term parking.

Performance Parameters:

Technical Specifications | |

Engine | |

Model | Cummins 6BTAA5.9 |

Type | Direct injection,supercharging, |

Number of cylinders ×Cylinder | 6×102×120 |

Displacement (L) | 5.9 |

Power(kw/rpm) | 133/2000 |

Maximum torque(N.M/rpm) | 708/1500 |

Bucket | |

Bucket volume(m3) | 1.06 |

Bucket width (mm) | 1325 |

Bucket teeth | 5 |

Digging Force | |

Bucket excavation force(KN) | 146 |

Arm excavation force(KN) | 107 |

Arm length(mm) | 2925 |

Hydraulic system | |

Type | Variable double plunger pump |

Maximum flow (L/in) | 2x224 |

Travel circuit pressure Mpa) | 34.3 |

Rotary circuit pressure(Mpa) | 25.5 |

Control oil circuit pressure(Mpa) | 3.9 |

Walking system | |

Walking motor | Variable plunger motor |

Number of track sections | 2×49 |

Walking speed (km/h) | 5.1/3.1 |

Traction force(KN) | 214 |

Climbing ability | 70%(35°) |

Number of supporting rollers | 2x9 |

Number of carrier wheel | 2x2 |

Operating Weight and Ground Pressure | |

Operating weight(Kg) | 22300 |

Track width(mm) | 600 |

Ground pressure(KPa) | 49.8 |

Slewing system | |

Type of slewing motor | Swash plate plunger motor |

Slewing speed(r/min) | 12.4 |

Braking form | Hydraulic braking |

Fuel tank (L) | 330 |

Cooling system(L) | 28 |

Engine oil volume(L) | 22 |

Hydraulic oil tank volume | 250 |

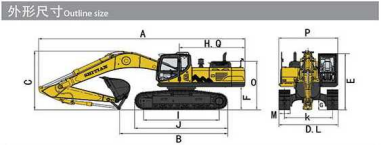

Arm Type | |

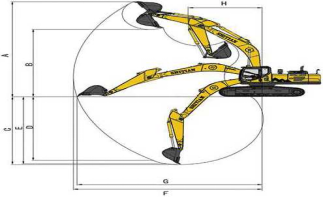

A.Total length(mm) | 9625 |

B.Grounding length (when transporting)(mm) | 4915 |

C.Overall height(to boom top)(mm) | 3075 |

D.Overall width(mm) | 2800 |

E.Overall height (to cab top)(mm) | 3055 |

F.Counterweight ground clearance(mm) | 1075 |

G.Min.ground clearance(mm) | 468 |

H.Tail slewing radius(mm) | 2925 |

I.Roller to roller distance(mm) | 3360 |

J.Track length(mm) | 4260 |

K.Track to track distance(mm) | 2380 |

L.Track width(mm) | 2800 |

M.Track plate width(mm) | 600 |

O.Hood height(mm) | 2395 |

P.Slewing platform width(mm) | 2725 |

Q.Distance from the center of rotation to the rear end(mm) | 2920 |

Excavator arm:

The movable arm is designed with a large cross-section, reinforcing the high load area for high durability, and optimized to avoid stress concentration.

Excavator Bucket Bar:

Bucket rods are reinforced according to the direction and magnitude of the force applied during operation.

Bucket rods are reinforced according to the direction and magnitude of the force applied during work, providing much higher strength.

Excavator bucket:

The bucket is made of high wear-resistant material, which extends the service life.

SH220-8 Excavator lower X-frame:

All processes of the lower X-frame are manufactured and processed with advanced equipment at home and abroad, and the important parts are subject to non-destructive testing; the track frame adopts a structural design of 7 supporting wheels and is equipped with 45 sections of track plates as standard, which ensures the reliability and stability of the whole vehicle under various complicated working conditions.

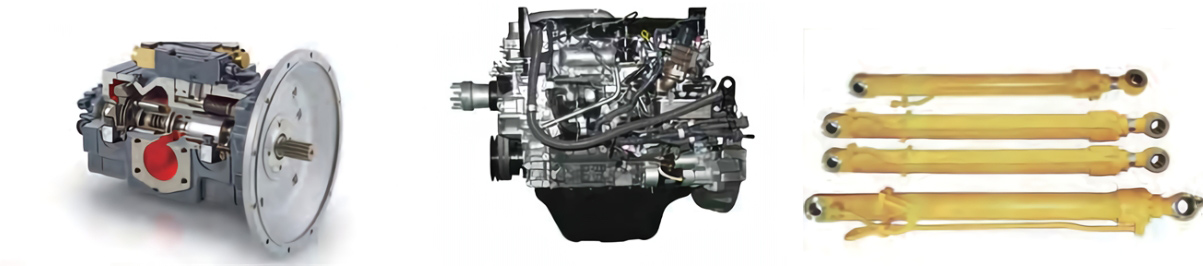

SH220-8 Excavator Hydraulic System:

Internationally renowned brand engine that meets China's Class III emission standard for off-road machinery diesel engines and adopts internationally advanced hydraulic system.

Excavator Specialized Oil Cylinder:

High-quality excavator-specific cylinders are optimized in a large number of ways for the sealing structure, buffer structure, mechanical structure and coating process in response to the characteristics of excavator cylinders, such as large working impact load, complex and variable control, and harsh working environment.

Excavator cooler parallel installation method:

Hydraulic oil radiator, water radiator and intercooler are arranged in parallel and horizontally, with good heat dissipation effect and easy cleaning.

Company Strength:

Shandong Shitian Heavy Industry Co., Ltd (Jining Shan re-energy) is located in Jining City, Shandong Province, high-tech zone technology industrial development zone. It is a high-tech enterprise specializing in the research, development and production of large excavators. For the large energy-saving excavator design, research and development and production of the leader, the development of hybrid large excavator SH520-9 energy-saving effect reached more than 30%.

In 2020, Jining Shan re-energy hybrid excavator production base project into the key support projects in Shandong Province, its conventional products SH380-9 using a full set of German Linde hydraulic system, strong digging performance, upholding the German industrial products, reliable and efficient design and manufacturing concepts; SH470-9, SH500-9, SH600 in the mines, highways, quarry conditions after decades of verification, known for high efficiency, energy saving The SH470-9, SH500-9, SH600 have been proven in mining, highway and quarry conditions for decades and are famous for high efficiency and energy saving.

Why Choose Us:

1. We have an independent R&D team and cooperate with 3 large collaborative teams to develop and upgrade products. There are 8 core R&D members and 28 R&D and trial production staff.

2. Utilizing the international advanced TQc total quality management system to implement quality control management.

3. 21 senior technical service personnel to provide a full range of after-sales service.

4. Advanced production management team, industry management experience of more than 15 years, to ensure the assembly quality.