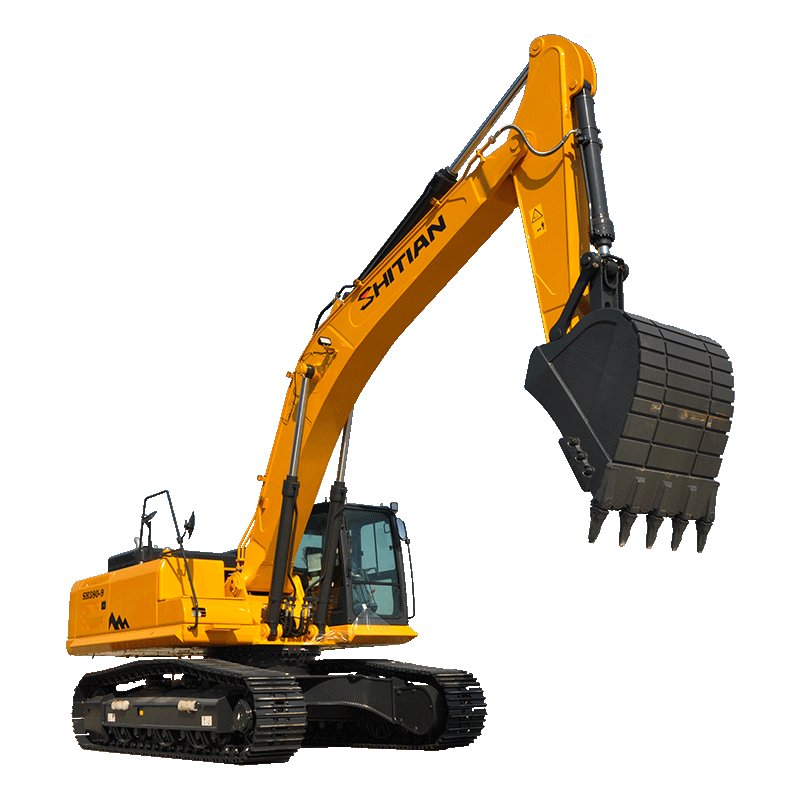

38 Ton Hydraulic Crawler Excavator

The 38-ton hydraulic crawler excavator features a new-generation power system that delivers high efficiency and strong performance while significantly reducing fuel consumption. Built with a robust structure and branded core components, it ensures long-term durability and higher residual value. Its quick-maintenance design saves time and costs, and compliance with national emission standards supports green, low-carbon operation.

Performance parameter

Working weight: 38000KG.

Bucket capacity: 1.62-1.82m³.

Engine: Isuzu

Model: 6HKIX

Rated power: 212kw/2000rpm

Scope of work:

Maximum excavation height: 10134mm

Maximum unloading height: 7182mm

Maximum digging depth: 7240mm.

Maximum vertical digging depth: 7170mm

Travel speed: 5km/h

Rotation speed: 9.7 RPM.

Product characteristics

Strong power: Equipped with a well-known brand engine, full power output, can meet a variety of heavy-duty excavation conditions, easy to cope with hard soil and rock excavation.

High excavation efficiency: Advanced hydraulic system, precise action, rapid response, for efficient excavation, loading and unloading operations. Some models adopt dual pump confluence technology, etc., which improves the action speed of the big arm and the small arm and further improves the work efficiency.

Good stability: The use of solid chassis and reinforced structural parts, the machine center of gravity is low and reasonable distribution, in complex terrain and harsh working conditions, can maintain good stability to ensure construction safety.

Operating comfort: A spacious and comfortable cab with ergonomic seats and operating handles reduces operator fatigue. At the same time, the cab has a good field of view, which is convenient for the operator to observe the working environment. Some models are also equipped with air conditioning, audio and other equipment to provide a more comfortable working environment.

Easy maintenance: The engine compartment and hydraulic system and other components are rationally arranged, convenient for daily inspection and maintenance. Some models have a fully open-door design, which makes it easy for maintenance personnel to get close to each component for maintenance and repair. In addition, it is also equipped with a centralized lubrication system, which reduces the maintenance workload and time.

Versatility: Can be equipped with a variety of accessories, such as crushing hammer, grab, milling machine, etc., through the quick connection device, can easily replace different accessories, to meet the diversified construction needs, to achieve a multi-purpose machine.

Product parameters:

Model | Unit | Parameter |

Engine | ||

Model | Isuzu 6HKIX | |

Form | 6-cylinder, inline, supercharged, intercooled | |

Cylinder X Bore X Stroke | (mm) | 6X115X125 |

Displacement | (L) | 7.79 |

Rated Power | (kw/rpm) | 212/2000 |

Bucket | ||

Bucket Capacity | (m³) | 1.62-1.82 |

Bucket Width | (mm) | 1571 |

Digging Power | ||

Bucket Lever Digging Power | (KN) | 190 |

Bucket Digging Power | (KN) | 230 |

Hydraulic System | ||

Hydraulic Pump Type | 2 variable piston pumps + 1 gear pump | |

Maximum Flow Rate | (L/min) | 2×330 |

Traveling Circuit Pressure | (MPa) | 36 |

Slewing Circuit Pressure | (MPa) | 25.5 |

System Pressure | (MPa) | 36 |

Walking System | ||

Traveling Motor | Axial Variable Piston Motors | |

Number of Track Plates | 2x49 | |

Traveling Speed | (km/h) | 5.0/3.0 |

Traction Force | (kN) | 280 |

Climbing Capacity | 70%(35°) | |

Number of Supporting Wheels | 2×8 | |

Number of Sprocket Wheels | 2×2 | |

Operating Weight and Ground Specific Pressure | ||

Operating Weight | (Kg) | 37000 |

Ground Specific Pressure | (KPa) | 62 |

Slewing System | ||

Slewing Speed | (r/min) | 9.7 |

Brake Type | Pressure relief, mechanical brake | |

Oil Capacity | ||

Fuel tank capacity | (L) | 580 |

Cooling System | (L) | 32.5 |

Engine oil volume | (L) | 33 |

Hydraulic tank filling volume/hydraulic system capacity | (L) | 380/450 |

Bucket Type | ||

A Overall Length | (mm) | 11161 |

B Grounding Length (For Transportation) | (mm) | 5872 |

C Overall Height (To Top of Boom) | (mm) | 3347 |

D Overall Width | (mm) | 3200 |

E Overall Height (To Top of Cab) | (mm) | 3293 |

F Counterweight Ground Clearance | (mm) | 1312 |

G Minimum Ground Clearance | (mm) | 565 |

H Tail Swing Radius | (mm) | 3438 |

I Wheelbase | (mm) | 4080 |

J Track Length | (mm) | 5044 |

K Track Spacing | (mm) | 2600 |

L Track Width | (mm) | 3200 |

M Track Plate Width | (mm) | 600 |

O Hood Height | (mm) | 2421 |

P Rotary Table Width | (mm) | 3195.3 |

Q Distance From Swing Center to Rear End | (mm) | 3438 |

Boom Type | ||

A Maximum Digging Height | (mm) | 10134 |

B Maximum Unloading Height | (mm) | 7182 |

C Maximum Digging Depth | (mm) | 7240 |

D Maximum Vertical Digging Depth | (mm) | 7170.5 |

E Maximum Digging Depth When Digging Out 8 Feet of Horizontal Surface | (mm) | 6812.5 |

F Maximum Digging Distance | (mm) | 11051 |

G Maximum Digging Distance at Ground Level | (mm) | 10839 |

H Minimum Turning Radius of Work Unit | (mm) | 4332 |

Product details:

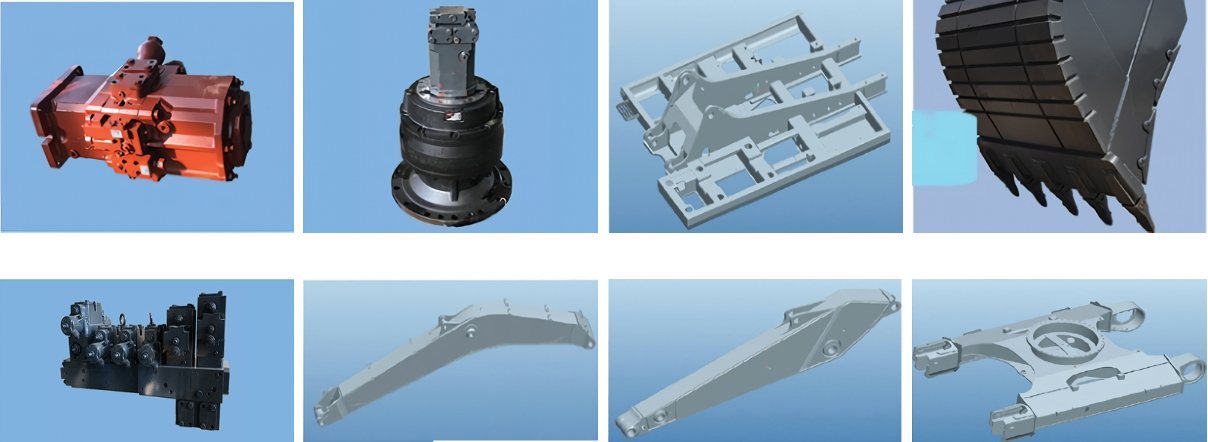

Core Component Performance

Linde Load-Sensitive Pumps: Leveraging load-sensing control, on-demand flow supply, and other technologies, they achieve excellent power matching, low power loss, strong self-priming capability, low noise, and sufficient pressure.

Linde Rotary Motors: Boasting advantages such as stable low-speed performance, high starting torque, low noise, compact structure, and efficient power transmission.

Load-Sensitive Synchronized Control Valves: Relying on pressure compensation and other designs, they ensure stable operation under complex working conditions while improving power utilization efficiency and system efficiency.

Key Structural Enhancement

Reinforced components including the arm, bucket bar, turntable, X-frame, and bucket are all optimized for durability and adaptability:

High-stress areas adopt high-strength materials, and key parts use forged components or special structures.

The cross-sectional strength of the X-frame is increased by over 35% compared with traditional models.

After reinforcement of the wear-prone parts of the bucket, its service life is extended by more than 20%.

The design of the turntable and drag chain wheels also reduces faults and ensures the durability of the travel system.

Overall Adaptability

The optimization of all components and structures is targeted at meeting the requirements of harsh working conditions and heavy-load operations. It balances power, efficiency, and durability, thereby comprehensively enhancing the overall performance of the equipment.

Supplementary Notes

Term Consistency: Core engineering terms align with industry conventions to ensure accuracy in technical documentation.

Data Clarity: Percentage increasesare translated as "increased by over 35%" and "extended by more than 20%" to clearly convey performance improvements, a standard practice in equipment specification translations.

Sentence Flow: Complex Chinese compound

Company Strength:

Shandong Shitian Heavy Industry Co., Ltd (Jining Shan re-energy) is located in Jining City, Shandong Province, high-tech zone technology industrial development zone. It is a high-tech enterprise specializing in the research, development and production of large excavators. For the large energy-saving excavator design, research and development and production of the leader, the development of hybrid large excavator SH520-9 energy-saving effect reached more than 30%.

In 2020, Jining Shan re-energy hybrid excavator production base project into the key support projects in Shandong Province, its conventional products SH380-9 using a full set of German Linde hydraulic system, strong digging performance, upholding the German industrial products, reliable and efficient design and manufacturing concepts; SH470-9, SH500-9, SH600 in the mines, highways, quarry conditions after decades of verification, known for high efficiency, energy saving The SH470-9, SH500-9, SH600 have been proven in mining, highway and quarry conditions for decades and are famous for high efficiency and energy saving.

Why Choose Us:

1. We have an independent R&D team and cooperate with 3 large collaborative teams to develop and upgrade products. There are 8 core R&D members and 28 R&D and trial production staff.

2. Utilizing the international advanced TQc total quality management system to implement quality control management.

3. 21 senior technical service personnel to provide a full range of after-sales service.

4. Advanced production management team, industry management experience of more than 15 years, to ensure the assembly quality.