21 Ton Hydraulic Excavator

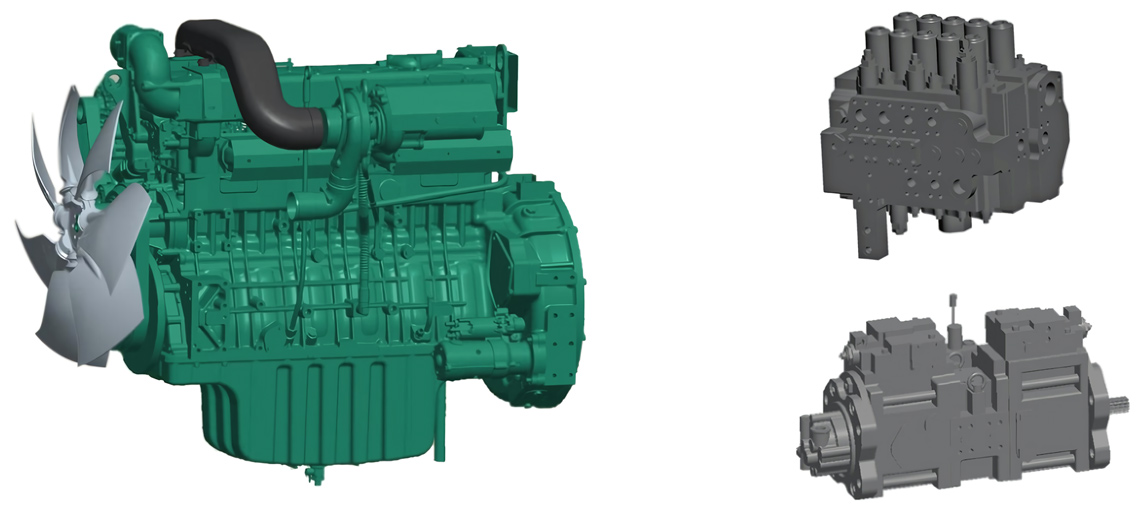

High-end system configuration

1. Highly adaptable turbocharged engine with high torque, able to adapt to high altitude operation and strong oil adaptability

2.High-end and reliable hydraulic system configuration, reduce energy loss, high efficiency and energy saving, good coordination of action.

Reinforced working device

1. Comprehensively optimize the design of structural parts, and strengthen the key stress positions, so that it is not afraid of harsh working conditions.

2. Bucket base plate, side plate and reinforcement plate are made of high strength wear-resistant material to improve the durability of the bucket.

3.Multi-specification movable arm, bucket bar and bucket can be easily combined to adapt to various working conditions.

Product description:

SH210W hydraulic excavator, configured with strong and reliable engine power system, lower fuel consumption, energy saving and environmental protection; configured with original imported hydraulic parts, stable and reliable quality, high efficiency; SH210W hydraulic excavator adopts domestic advanced intelligent electronic control system and high-strength structural parts, stronger adaptability to working conditions, more energy-saving, efficient and environmentally friendly. Intelligent information terminal embedded GPS system enhances the intelligent level of the whole machine and effectively protects the safety of customer's assets.

Product parameter:

Engine | |

Model | WP7 |

Form | Common Rail Water-cooled Inline-6 Turbocharged |

Displacement (L) | 7.47 |

Rated power (kW/rpm) | 116/2000 |

Bucket | |

Bucket capacity | 0.45~1.0(0.9) |

Excavating Power | |

Bucket Bar force (kN) | 92.5 |

Bucket digging force (kN) | 115 |

Traveling System | |

Traveling motor | Axial Variable Piston Motor |

Traveling speed (km/h) | 3/5 |

Traction force (kN) | 201 |

Climbing ability | 70% (35°) |

Hydraulic system | |

Hydraulic pump form | Axial variable piston pumps |

Rated working flow(L/min) | 2x218 |

Rotary System | |

Maximum rotary speed(r/min) | 11.5 |

Brake type | Pressure relief Mechanical brake |

Operating weight and grounding specific pressure | |

Weight of the whole machine(kg) | 20500 |

Ground pressure(kPa) | 45 |

Oil capacity | |

Fuel tank capacity(L) | 340 |

Cooling system(L) | 25 |

Engine oil capacity(L) | 24 |

Hydraulic oil tank/system capacity(L) | 250/420 |

Total length (mm) | 9543 |

Grounding length (for transportation) (mm) | 4860 |

Overall height (to top of arm) (mm) | 3039 |

Overall width (mm) | 2800 |

Overall height (to top of cab) (mm) | 2977 |

Counterweight Ground Clearance (mm) | 1120 |

Minimum Ground Clearance (mm) | 470 |

Tail radius (mm) | 2905 |

Track length (mm) | 4160 |

Track Gauge (mm) | 2200 |

Track width (mm) | 2800 |

Standard track plate width (mm) | 600 |

Slewing platform width (mm) | 2726 |

Slewing center to rear end distance (mm) | 2853 |

Maximum digging height (mm) | 10029 |

Maximum unloading height (mm) | 7132 |

Maximum digging depth (mm) | 6541 |

Maximum vertical digging depth (mm) | 5985 |

Maximum digging distance (mm) | 9860 |

Maximum digging distance at ground level (mm) | 9673 |

Minimum turning radius of working device(mm) | 3041 |

High-end system configuration

1. Highly adaptable turbocharged engine with high torque, able to adapt to high altitude operation and strong oil adaptability

2.High-end and reliable hydraulic system configuration, reduce energy loss, high efficiency and energy saving, good coordination of action.

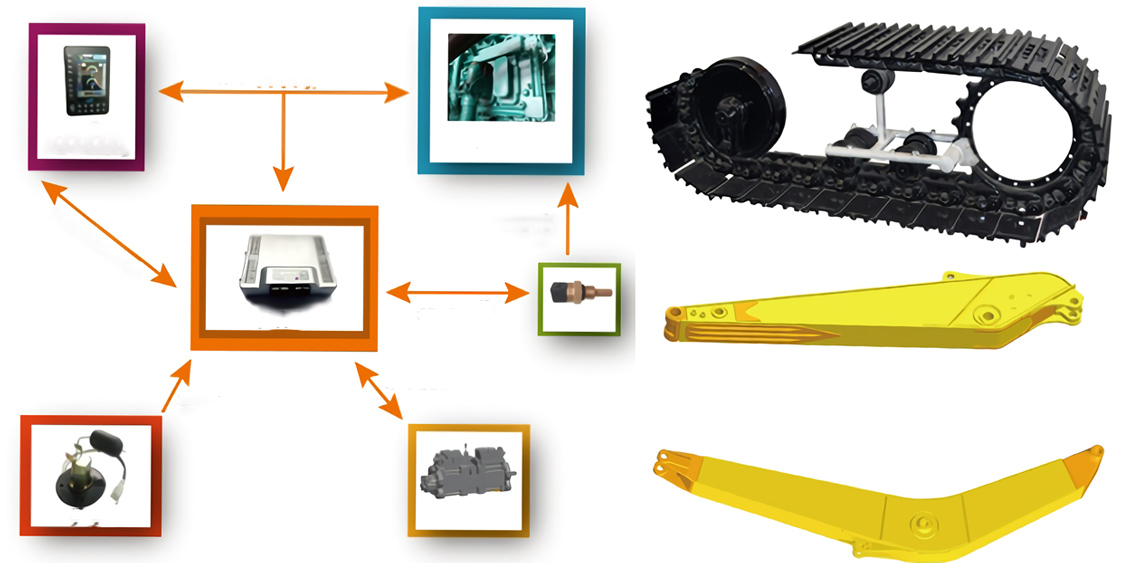

Reinforced working device

1. Comprehensively optimize the design of structural parts, and strengthen the key stress positions, so that it is not afraid of harsh working conditions.

2. Bucket base plate, side plate and reinforcement plate are made of high strength wear-resistant material to improve the durability of the bucket.

3.Multi-specification movable arm, bucket bar and bucket can be easily combined to adapt to various working conditions.

Spacious and comfortable operating environment

1. Injection molding interior, according to the ergonomics of the interior color effectively collocation, not easy to cause visual fatigue of the operator

2. Large space, wide field of vision, reasonable arrangement of maneuvering devices, convenient and comfortable operation.

3. High-power air-conditioning, floating seats, comfortable ride.

Four wheels and one belt

1.30 years of experience in R&D and manufacturing of four wheels and one belt, world-leading technology 2.World's top forging heat treatment technology, stable and reliable quality.

Intelligent electronic control, optimal power control

1.Intelligent control system realizes the best match between power system and hydraulic system, which improves working efficiency and reduces fuel consumption.

2. Man-machine friendly new generation intelligent electronic control system, let your machine working status in the grasp of preset

H (Heavy duty mode) M (Economy mode) L (Light duty mode) F (Fine mode) B (Crusher mode)

Five working modes, easy to switch

3. Through the cloud platform, you can view the vehicle's position, running track, working status and other related information at any time.

Company Strength:

Shandong Shitian Heavy Industry Co., Ltd (Jining Shan re-energy) is located in Jining City, Shandong Province, high-tech zone technology industrial development zone. It is a high-tech enterprise specializing in the research, development and production of large excavators. For the large energy-saving excavator design, research and development and production of the leader, the development of hybrid large excavator SH520-9 energy-saving effect reached more than 30%.

In 2020, Jining Shan re-energy hybrid excavator production base project into the key support projects in Shandong Province, its conventional products SH380-9 using a full set of German Linde hydraulic system, strong digging performance, upholding the German industrial products, reliable and efficient design and manufacturing concepts; SH470-9, SH500-9, SH600 in the mines, highways, quarry conditions after decades of verification, known for high efficiency, energy saving The SH470-9, SH500-9, SH600 have been proven in mining, highway and quarry conditions for decades and are famous for high efficiency and energy saving.