60 Ton Hydraulic Excavator

This 60-ton hydraulic excavator delivers exceptional cost efficiency and high productivity. Its advanced power system and intelligent hydraulic technology significantly reduce fuel consumption and maintenance costs, while the durable construction ensures long-term reliability and high residual value. The equipment provides powerful digging force alongside rapid cycling operations, and with its low-noise eco-friendly cabin and green emission standards, it stands as an ideal choice that balances efficiency and sustainability.

Product description:

The SH600-9 hydraulic crawler excavator integrates an advanced electro-hydraulic control system and is equipped with a 5.7-inch high-brightness large screen that delivers clear and detailed display. It dynamically presents real-time operational data of the entire machine, making critical information instantly accessible and enabling operators to fully monitor the equipment status. Communication between the engine ECU and the controller via CAN-BUS ensures precise power control and efficient data interaction, significantly enhancing overall operational efficiency. Superior manufacturing craftsmanship provides excellent protection performance, guaranteeing stable and reliable operation even under harsh working conditions.

This machine adopts a multi-neural derived adaptive PDI intelligent control algorithm. When errors are large, it automatically cancels the integral term to accelerate response; when errors are small, it introduces integral control to improve accuracy. This effectively prevents saturation, reduces steady-state error, and significantly optimizes both dynamic and static performance of the system. While achieving precise control, this algorithm also offers online energy-saving advantages, providing customers with a solution that combines high performance and low energy consumption.

Product parameters:

Model | Unit | Parameter |

Engine | ||

Model | Cummins QSM11-C400 | |

Form | 6-cylinder, inline, supercharged, intercooled | |

Bore X Stroke | (mm) | 125X150 |

Displacement | (L) | 10.8 |

Rated Power | (kw/rpm) | 298/1800 |

Bucket | ||

Bucket Capacity | (m³) | 2.5-3.5 |

Bucket Width | (mm) | 1968 |

Digging Power | ||

Bucket Lever Digging Power | (KN) | 271 |

Bucket Digging Power | (KN) | 328 |

Hydraulic System | ||

Form | Negative Flow | |

Maximum Flow Rate | (L/min) | 874 |

Traveling Circuit Pressure | (MPa) | 34.3 |

Slewing Circuit Pressure | (MPa) | 28.4 |

Control Circuit Pressure | (MPa) | 3.9 |

Walking System | ||

Traveling Motor | Axial Variable Piston Motors | |

Pilot System Pressure | 4.9MPa | |

Traveling Speed | (km/h) | 3.55/6.1 |

Traction Force | (kN) | 349 |

Climbing Capacity | 70%(35°) | |

Number of Supporting Wheels | 9 | |

Number of Sprocket Wheels | 2 | |

Operating Weight and Ground Specific Pressure | ||

Operating Weight | (Kg) | 55900 |

Ground Specific Pressure | (KPa) | 85.3 |

Slewing System | ||

Slewing Speed | (r/min) | 10.4 |

Brake Type | Disc spring loaded | |

Oil Capacity | ||

Fuel tank capacity | (L) | 630 |

Cooling System | (L) | 39 |

Engine oil volume | (L) | 38 |

Hydraulic tank filling volume | (L) | 490/610 |

Bucket type | ||

A Overall Length | (mm) | 10252 |

B Grounding Length (For Transportation) | (mm) | 4414 |

C Overall Height (To Top of Boom) | (mm) | 4308 |

D Overall Width | (mm) | 3718/4154 |

E Overall Height (To Top of Cab) | (mm) | 3379 |

F Counterweight Ground Clearance | (mm) | 1426 |

G Minimum Ground Clearance | (mm) | 1382 |

H Tail Swing Radius | (mm) | 3822 |

I Wheelbase | (mm) | 4414 |

J Track Length | (mm) | 5487 |

K Track Spacing | (mm) | 2392/2890 |

L Track Width | (mm) | 600 |

M Track Plate Width | (mm) | 228 |

O Hood Height | (mm) | 2984 |

P Rotary Table Width | (mm) | 3165/3543 |

Q Distance From Swing Center to Rear End | (mm) | 3774 |

Boom Type | ||

A Maximum Digging Height | (mm) | 10252 |

B Maximum Unloading Height | (mm) | 7150 |

C Maximum Digging Depth | (mm) | 7114 |

D Maximum Vertical Digging Depth | (mm) | 4522 |

E Maximum Digging Depth When Digging Out 8 Feet of Horizontal Surface | (mm) | 6945 |

F Maximum Digging Distance | (mm) | 11406 |

G Maximum Digging Distance at Ground Level | (mm) | 11176 |

H Minimum Turning Radius of Work Unit | (mm) | 4840 |

Construction site:

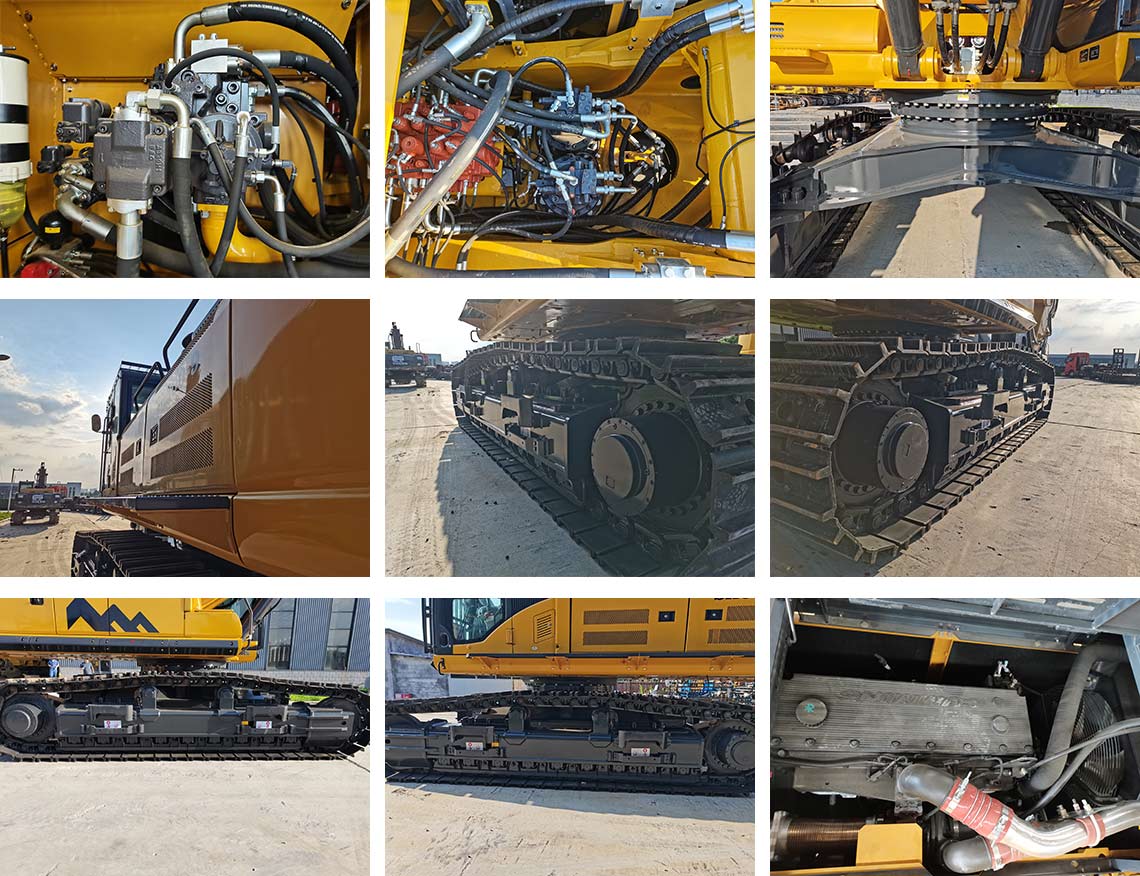

Product details:

Why Choose Us:

1. We have an independent R&D team and cooperate with 3 large collaborative teams to develop and upgrade products. There are 8 core R&D members and 28 R&D and trial production staff.

2. Utilizing the international advanced TQc total quality management system to implement quality control management.

3. 21 senior technical service personnel to provide a full range of after-sales service.

4. Advanced production management team, industry management experience of more than 15 years, to ensure the assembly quality.