610 HP Crawler Bulldozer

Product advantage:

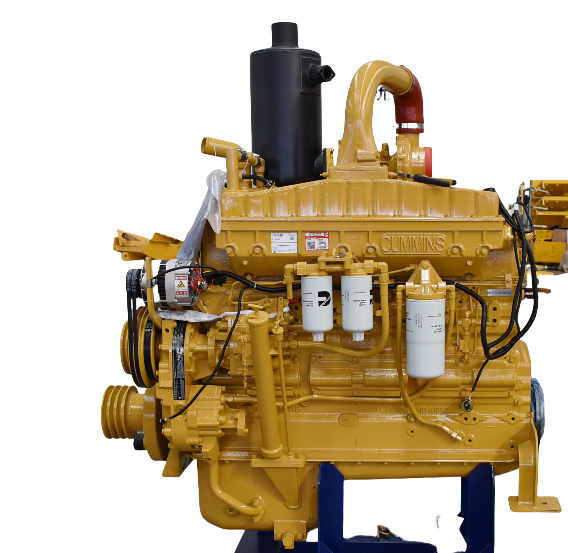

QSK19 electronic control engine has obvious advantages, the electronic control system accurately controls fuel, saves fuel under light load and uses turbocharging for heavy load; Durable structure, excellent materials and refined key components; Modular design facilitates assembly and maintenance; There is also a global service network, which can be used for remote guidance or on-site maintenance, and is a high-quality power for construction machinery.

The design of engine and transmission system of crawler bulldozer is guided by the core requirements of complex operation scenes, and forms deep adaptation in three dimensions: environmental protection, reliability and economy, so as to ensure that the whole machine can run stably and efficiently under severe working conditions such as heavy load in mines, steep slope operation in infrastructure and leveling of complex municipal sites. In terms of engine configuration, the whole machine is equipped with a high-performance power unit with common rail fuel system (MCRS). The system collects multi-dimensional working condition data such as engine speed, load and temperature in real time through high-precision electronic control unit (ECU), and accurately adjusts fuel injection pressure and injection timing—— with millisecond response speed. Compared with the traditional mechanical fuel injection system, the fluctuation of fuel injection pressure can be controlled in a very small range, which can realize the atomization effect of fuel in the combustion chamber, fully mix fuel with air, and reduce the fuel loss of incomplete combustion from the combustion source. This efficient combustion mode can not only significantly reduce the emission of pollutants such as nitrogen oxides and particulate matter, but also easily meet the Euro A/III emission standards and meet the requirements of environmental protection construction. It can greatly reduce the generation of carbon deposits in the combustion process, prevent carbon particles from adhering to the valve, piston top and fuel nozzle, delay the aging speed of key components of the engine, reduce the failures such as unstable idle speed and power drop caused by carbon deposition, and ensure the engine to be in a stable output state for a long time. At the same time, the SECCO double pre-filtration air intake system matched with the engine builds a double air purification defense line to provide a clean air intake environment for the engine. The system adopts a two-stage filtration structure of "coarse filtration+fine filtration": in the first stage of coarse filtration, more than 80% of large particle dust and sand in the air are separated and discharged by cyclone separation technology to avoid blockage caused by large impurities directly entering the fine filtration link; The second stage of fine filtration adopts high-efficiency composite filter material, which can filter micron-sized fine dust and impurities in the air, and the filtration efficiency far exceeds that of the traditional single-stage filtration system. Even in high dust working environment such as mine dust and desert drought, it can effectively prevent particles from entering the engine cylinder, avoid early damage of core moving parts such as piston, cylinder wall and piston ring due to abrasive wear, reduce serious faults such as engine cylinder pulling and gas leakage from the source, significantly prolong the overhaul interval and overall service life of the engine, and reduce the later maintenance cost of users.

In terms of transmission system, the torque converter equipped with the whole machine adopts hydraulic transmission design with locking function, and with flexible transmission mode switching, it perfectly adapts to the power demand of different operation scenarios. The core advantage of the torque converter is that it can dynamically adjust the output torque according to the load change: when facing the high-intensity working load such as hard rock and frozen soil, or encountering great resistance when working on steep slopes, the torque converter can automatically increase the output torque, provide strong traction for the whole machine, and avoid engine flameout caused by excessive load; When the working resistance decreases, the torque output is adjusted accordingly, so as to prevent power waste and realize the intelligent adaptation of "power supply on demand". In the switching of transmission mode, during low-speed operation (such as fine site leveling and accurate shovel loading of bucket), the system maintains the hydraulic transmission state, and uses the buffering characteristics of hydraulic oil to realize the smooth transmission of power, avoiding the impact of mechanical transmission, making the operation more accurate and reducing the operation error caused by power fluctuation; When the whole machine enters the high-speed transition mode, the torque converter automatically switches to the mechanical transmission mode, and the power loss in the hydraulic transmission process is reduced through rigid connection, which can save 10%-15% fuel consumption compared with the traditional single hydraulic transmission system. This dual advantage of "low-speed hydraulic stability and high-speed machinery fuel saving" can not only ensure the construction quality of complex operations, but also reduce the fuel cost of long-term operation and significantly improve the economy of the whole machine.

Basic parameters | Performan specifications | ||

Workingweight | 70630(KG) | Type of scarifier | single |

power | 450/1800(kw/rpm) | Loosening depth | 143 |

Blade capacity | 18.9m3 | Lifting height of scarifier | 110(mm) |

Engine Model | QSK19 | ||

Dimensions | Operating scope and parameters | ||

Overall length | 10390(mm) | Blade type | half |

Overall width | 4690(mm) | Blade width | 469(mm) |

Transport height | 4370(mm) | Blade height | 225(mm) |

Number of track shoes | 40 | Blade lifting height | 166(mm) |

Track shoe width | 610(710/810)(mm) | ||

Track center distance | 2500(mm) | ||