1.5 Ton Electric Excavator

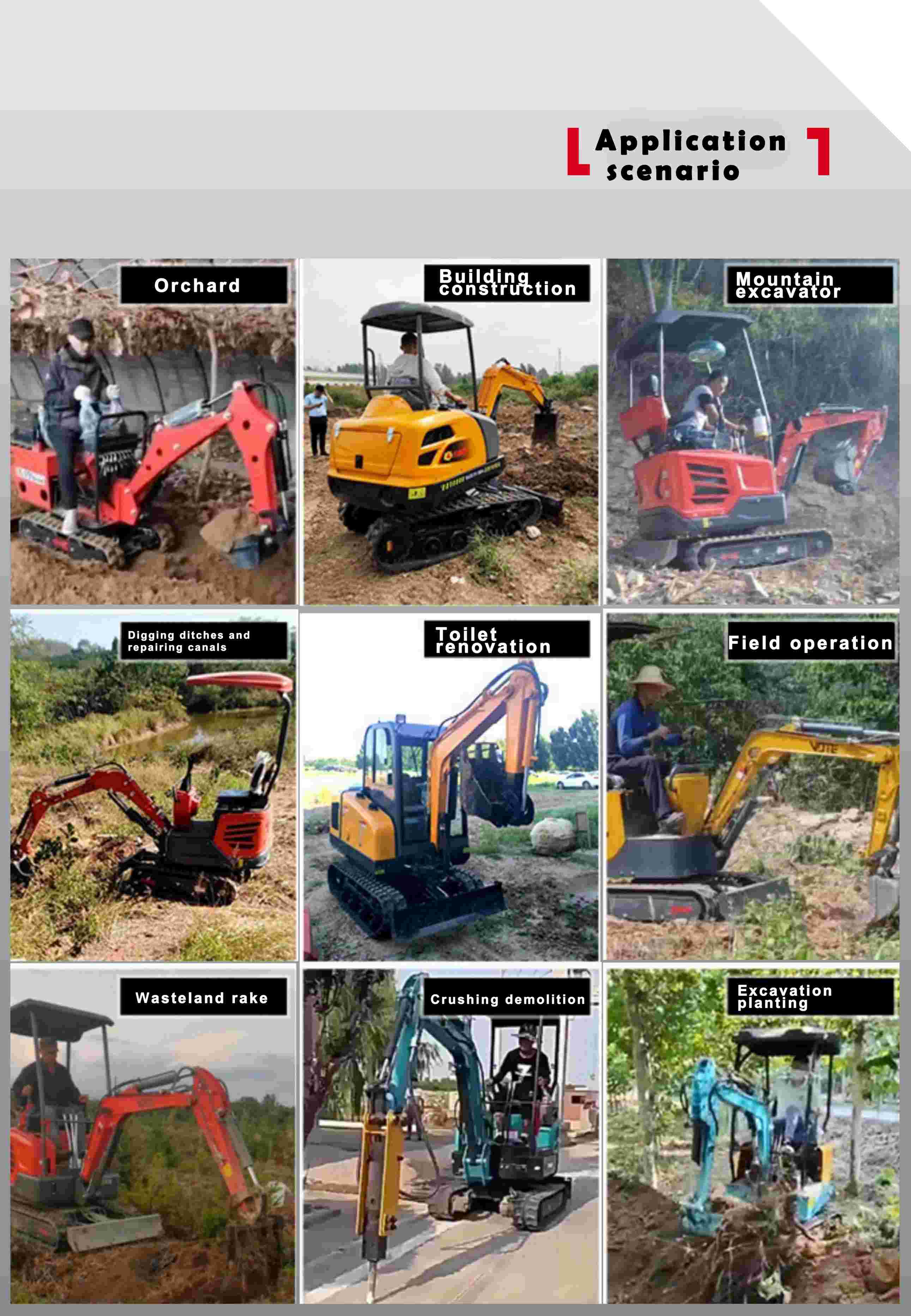

The 1.5-ton electric excavator is an eco-friendly, economical, and intelligent compact construction machine. Driven purely by electricity, it features zero emissions and low-noise operation, making it particularly suitable for environmentally sensitive sites such as indoor areas and tunnels. With its compact structure and strong mobility, it easily adapts to narrow spaces. It also offers low operating costs and supports intelligent monitoring and multi-functional attachments, enabling efficient performance in various tasks such as excavation, crushing, and drilling.

This 1.5-ton electric excavator integrates advanced electric drive technology, intelligent control and multi-functional expansion, demonstrating outstanding comprehensive performance and significant application advantages, which are specifically reflected in the following aspects:

Outstanding performance in environmental protection and energy efficiency

This equipment adopts high-performance motors as the power core, achieving zero exhaust emissions throughout the operation process and eliminating the inherent exhaust pollution problems of traditional diesel equipment. It especially meets the strict environmental requirements of indoor construction, tunnel operations, garden landscapes and ecologically sensitive areas. The sound level of the motor during operation is significantly lower than that of the diesel engine, greatly reducing noise interference and facilitating the maintenance of a quiet and comfortable working atmosphere. In terms of energy utilization, the motor system has an excellent energy conversion efficiency. Compared with fuel-driven equipment, it can significantly reduce energy consumption per unit time and effectively control operating costs.

it has outstanding spatial adaptability and operational flexibility

The whole machine is compaciously designed with excellent maneuverability. With its small size and light overall weight, it can flexibly move through urban streets, courtyards and various restricted working conditions, demonstrating superior spatial passability. Some models offer two traveling mechanism options: rubber tracks and wheeled chassis, further enhancing the convenience of equipment transfer and on-site adaptation. The hydraulic system has been optimized in design, featuring sensitive operation response and clear logic. This effectively lowers the skill threshold and training burden for operators, enabling even non-skilled drivers to master basic operation skills in a short period of time.

it should have good economic and investment value

Electric excavators use electricity as their energy source, and their unit energy consumption cost is much lower than that of diesel. Combined with the characteristics of the motor itself, such as simple structure, low failure rate and less maintenance requirements, it can effectively reduce the comprehensive operating expenses during long-term use. Although its initial purchase cost may be slightly higher than that of traditional models of the same level, the energy and maintenance costs saved throughout its life cycle will bring about a more competitive total cost of ownership (TCO) and return on investment (ROI).

Potential for intelligent and multi-functional expansion

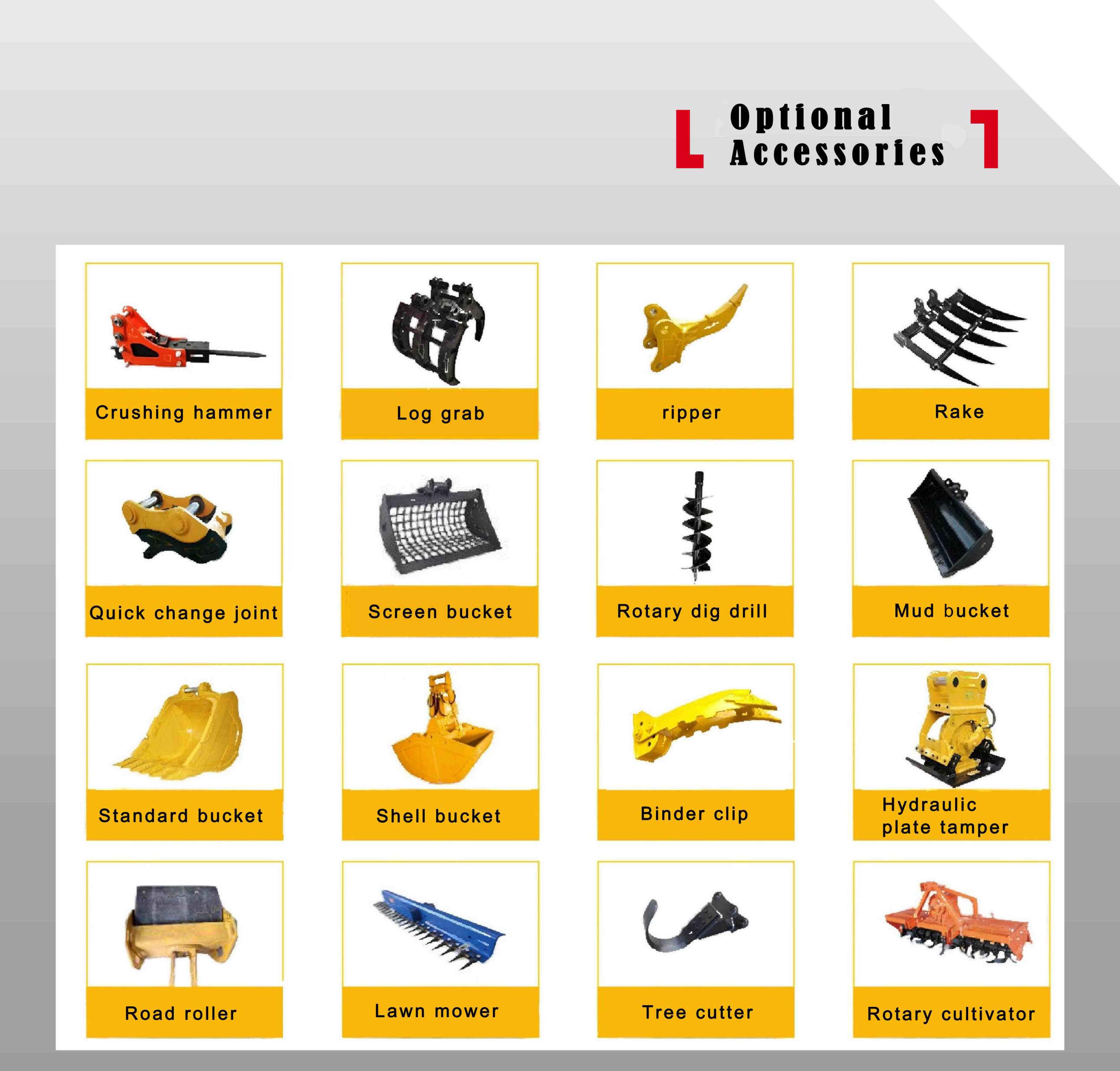

Some high-end configurations are integrated with intelligent control platforms, supporting remote equipment status monitoring, fault early warning and diagnostic analysis, which helps to improve the accuracy of construction management and the efficiency of equipment operation and maintenance. This model can also be quickly connected to various hydraulic attachments, including but not limited to standard buckets, breakers, hydraulic drills, etc., easily achieving multi-functional composite applications such as excavation, crushing, drilling, and material handling, effectively expanding the operation boundaries and application scenarios of the equipment.

Model | Parameter | Model | Parameter |

weight(KG) | 1680 | Maximum excavation dig deep C | 2100 |

Transport length | 2350 | Maximum vertical digging depth D | 1585 |

Wooden case lengthA | 2890 | Maximum excavation radius E | 3150 |

Overall widthB | 1100 | Minimum radius of turn F | 1587 |

Total heightC | 2240 | Standard engine brand | KubotaD722 |

Turntable widthD | 990 | Emission standard | Country 4 / US 4 / Euro 5 |

Total chassis widthE | 1100 | Engine power (KW | 10.2KW/2500RPM |

Track width F | 180 | Telescopic side swing | sway |

Wheel track G | 1082 | Standard with bucket(MM) | 400 |

gauge H | 895 | Bucket capacity(M) | 0 |

Platform clearance I | 400 | cab | optional |

Minimum ground clearance J | 140 | air conditioner | optional |

Maximum excavation height A | 2690 | ||

Maximum unloading height B | 1780 |

This 1.5-ton electric excavator, with its lightweight body and compact structure, is particularly suitable for use in space-constrained working conditions. It can not only flexibly move through small construction sites, indoor work sites, orchards and vegetable greenhouses and other narrow environments, but also smoothly pass through most narrow doors and narrow passages, easily entering areas that are difficult for traditional excavators to reach.

Thanks to its compact body design, this device has an extremely small turning radius, enabling flexible steering and precise operation even in limited Spaces. Operators can quickly adjust the working position and Angle, effectively reducing the time consumption caused by frequent equipment movement, thereby significantly improving work efficiency.

FAQ:

1.What products does the company mainly produce?

We focus on the research and development, design and production of a full range of excavators, bulldozers and other construction machinery, and are a leading enterprise in the field of large-scale energy-saving mining machinery and micro electric machinery in China. Our mining equipment and micro electric products have reached the international advanced level in technology and can provide customized solutions based on the specific needs of customers.

2. What are the payment methods?

The payment terms we usually accept are as follows: 30% of the total order amount should be prepaid as a deposit after the contract is signed, and the remaining 70% of the payment should be settled before the goods are dispatched.

3. How long is the delivery cycle?

The standard delivery time is 30 to 45 days after receiving the deposit. Inventory products can be dispatched immediately, while custom orders may require additional delivery time, depending on the specifications.

4. Which transportation methods are supported?

We offer flexible and diverse logistics solutions, covering various routes such as road, sea and air transportation. Most of the equipment can be transported by container or bulk cargo to ensure safe and efficient delivery.